- Lithium Golf Cart Battery

- Forklift Lithium Battery

-

48V

- 48V 210Ah

- 48V 300Ah

- 48V 420Ah (949 x 349 x 569 mm)

- 48V 420Ah (950 x 421 x 450 mm)

- 48V 456Ah

- 48V 460Ah (830 x 630 x 590 mm)

- 48V 460Ah (950 x 421 x 450 mm)

- 48V 460Ah (800 x 630 x 600 mm)

- 48V 460Ah (820 x 660 x 470 mm)

- 48V 500Ah

- 48V 560Ah (810 x 630 x 600 mm)

- 48V 560Ah (950 x 592 x 450 mm)

- 48V 600Ah

- 48V 630Ah

-

48V

- 12V Lithium Battery

12V 150Ah Lithium RV Battery

Bluetooth App | BCI Group 31

LiFePO4 Lithium

Discharge Temperature -20°C ~ 65°C

Fast Charger 14.6V 50A

Solar MPPT Charging - 24V Lithium Battery

- 36V Lithium Battery

- 48V Lithium Battery

-

48V LiFePO4 Battery

- 48V 50Ah

- 48V 50Ah (for Golf Carts)

- 48V 60Ah (8D)

- 48V 100Ah (8D)

- 48V 100Ah

- 48V 100Ah (Discharge 100A for Golf Carts)

- 48V 100Ah (Discharge 150A for Golf Carts)

- 48V 100Ah (Discharge 200A for Golf Carts)

- 48V 150Ah (for Golf Carts)

- 48V 160Ah (Discharge 100A for Golf Carts)

- 48V 160Ah (Discharge 160A for Golf Carts)

-

48V LiFePO4 Battery

- 60V Lithium Battery

-

60V LiFePO4 Battery

- 60V 20Ah

- 60V 30Ah

- 60V 50Ah

- 60V 50Ah (Small Size / Side Terminal)

- 60V 100Ah (for Electric Motocycle, Electric Scooter, LSV, AGV)

- 60V 100Ah (for Forklift, AGV, Electric Scooter, Sweeper)

- 60V 150Ah (E-Motocycle / E-Scooter / E-Tricycle / Tour LSV)

- 60V 200Ah (for Forklift, AGV, Electric Scooter, Sweeper)

-

60V LiFePO4 Battery

- 72V~96V Lithium Battery

- Rack-mounted Lithium Battery

- E-Bike Battery

- All-in-One Home-ESS

- Wall-mount Battery ESS

-

Home-ESS Lithium Battery PowerWall

- 24V 100Ah 2.4kWh PW24100-S PowerWall

- 48V 50Ah 2.4kWh PW4850-S PowerWall

- 48V 50Ah 2.56kWh PW5150-S PowerWall

- 48V 100Ah 5.12kWh PW51100-F PowerWall (IP65)

- 48V 100Ah 5.12kWh PW51100-S PowerWall

- 48V 100Ah 5.12kWh PW51100-H PowerWall

- 48V 200Ah 10kWh PW51200-H PowerWall

- 48V 300Ah 15kWh PW51300-H PowerWall

PowerWall 51.2V 100Ah LiFePO4 Lithium Battery

Highly popular in Asia and Eastern Europe.

CE Certification | Home-ESS -

Home-ESS Lithium Battery PowerWall

- Portable Power Stations

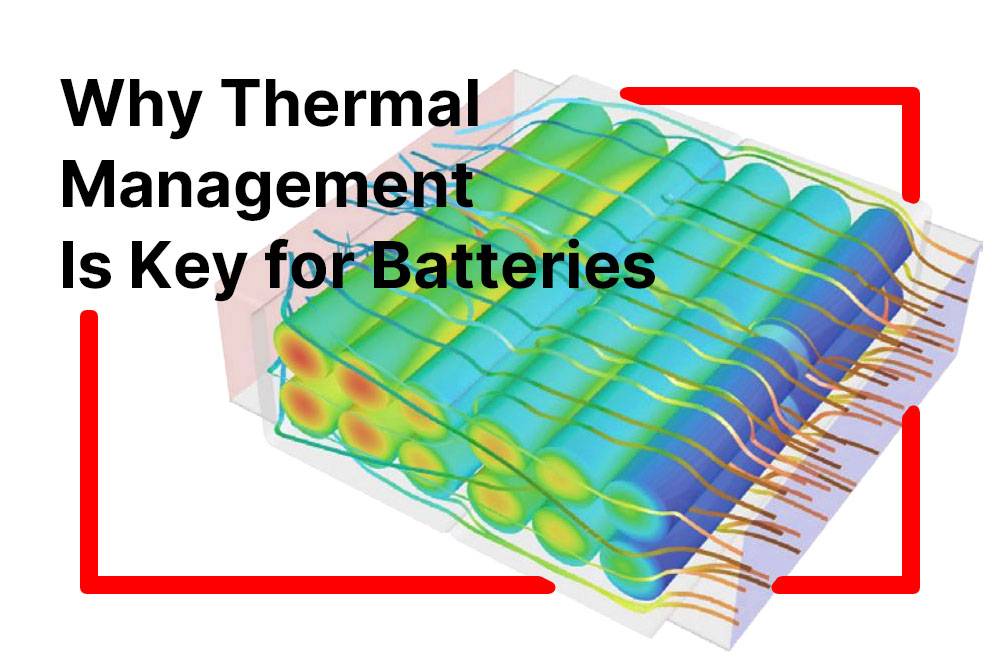

Why Thermal Management is Key for Batteries: Innovative Solutions Explained

Thermal management is essential for the effective operation and longevity of batteries, particularly in electric vehicles and renewable energy applications. This article explores the importance of thermal management, how various battery chemistries respond to temperature changes, common techniques used, and innovative solutions being developed to enhance performance.

What is thermal management in batteries?

Thermal management refers to the methods and technologies employed to control the temperature of batteries during operation. Effective thermal management ensures that batteries operate within their optimal temperature range, which is crucial for maximizing performance, safety, and lifespan. It involves both heating and cooling strategies to maintain a stable environment for the battery cells.Chart: Thermal Management Overview

| Aspect | Description |

|---|---|

| Definition | Control of battery temperature during operation |

| Importance | Maximizes performance and lifespan |

| Methods | Heating and cooling strategies |

Why is thermal management crucial for battery performance?

Thermal management is vital for several reasons:

- Performance Optimization: Batteries perform best within specific temperature ranges. Operating outside these ranges can lead to reduced efficiency and power output.

- Safety Assurance: Excessive heat can cause thermal runaway, leading to fires or explosions. Proper thermal management mitigates these risks.

- Longevity: Keeping batteries at optimal temperatures helps prevent degradation of materials, extending their usable life.

Chart: Importance of Thermal Management

| Reason | Explanation |

|---|---|

| Performance Optimization | Ensures maximum efficiency |

| Safety Assurance | Reduces risk of overheating and failure |

| Longevity | Extends the life of the battery |

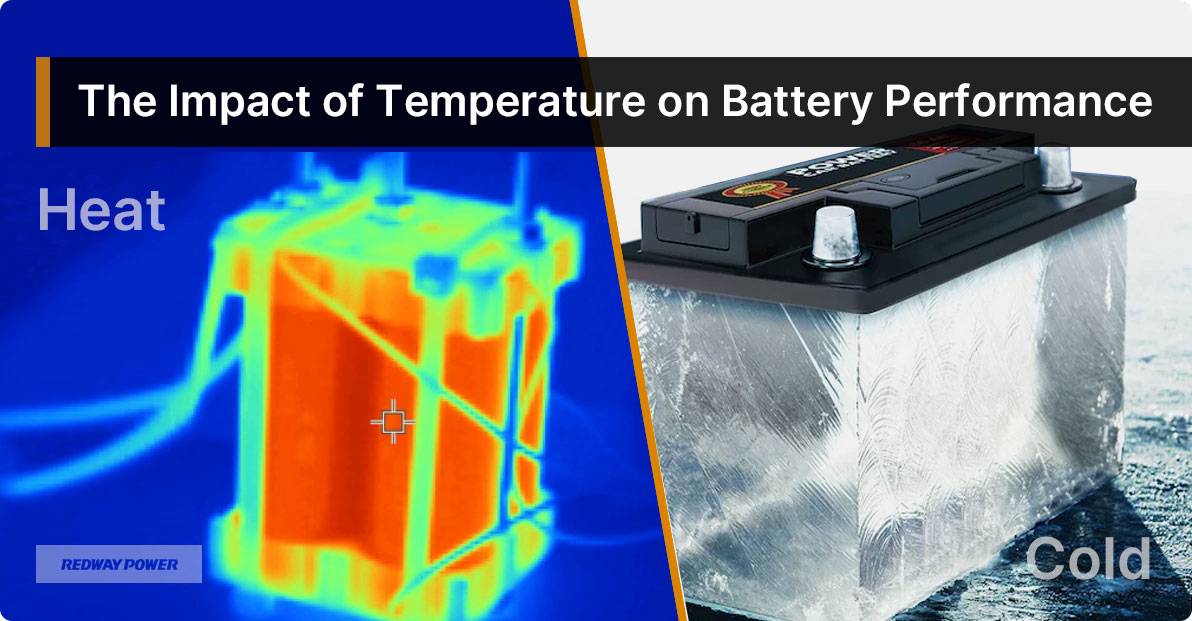

How do different battery chemistries respond to temperature changes?

Different battery chemistries have varying responses to temperature changes:

- Lithium-Ion Batteries: These typically operate best between 15°C and 35°C (59°F and 95°F). Extreme temperatures can cause capacity loss or safety issues.

- Nickel-Metal Hydride (NiMH): NiMH batteries perform well at moderate temperatures but can suffer from reduced capacity at high temperatures.

- Lead-Acid Batteries: These are less sensitive to temperature but still benefit from moderate conditions; extreme cold can reduce their performance significantly.

Chart: Battery Chemistry Temperature Response

| Battery Type | Optimal Temperature Range | Temperature Sensitivity |

|---|---|---|

| Lithium-Ion | 15°C to 35°C | High sensitivity to extremes |

| Nickel-Metal Hydride | 20°C to 30°C | Moderate sensitivity |

| Lead-Acid | -20°C to 50°C | Less sensitive but cold affects capacity |

What are common thermal management techniques used in battery systems?

Several techniques are commonly employed to manage battery temperatures effectively:

- Active Cooling Systems: These include fans or liquid cooling systems that actively remove heat from the battery pack during operation.

- Passive Cooling Systems: These rely on natural convection or heat sinks to dissipate heat without additional energy input.

- Phase Change Materials (PCMs): PCMs absorb excess heat during charging or discharging, maintaining stable temperatures.

- Thermal Insulation: Insulating materials help maintain temperature by reducing heat loss or gain from external sources.

Chart: Thermal Management Techniques

| Technique | Description |

|---|---|

| Active Cooling | Uses fans or liquid systems |

| Passive Cooling | Relies on natural convection |

| Phase Change Materials | Absorb excess heat during operation |

| Thermal Insulation | Reduces heat exchange with the environment |

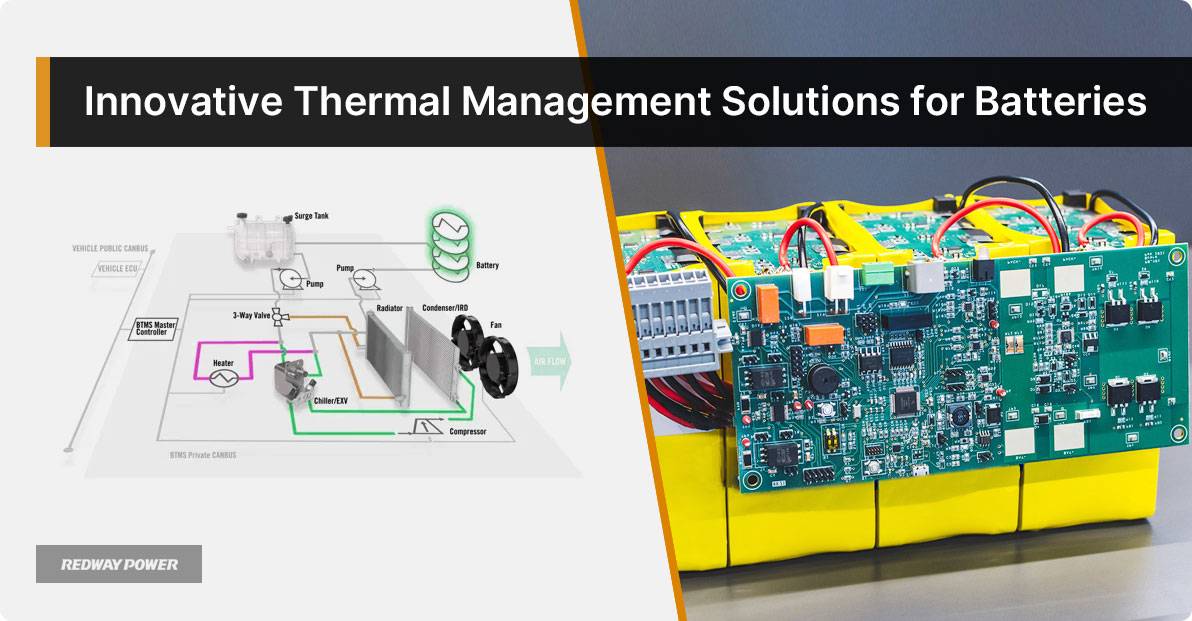

What innovations are being developed for better thermal management?

Innovations in thermal management technology focus on enhancing efficiency and safety:

- Smart Thermal Management Systems: These use sensors and algorithms to monitor temperatures in real-time, adjusting cooling efforts as needed.

- Advanced Materials: Research into new materials that provide better insulation or enhanced heat dissipation capabilities is ongoing.

- Integrated Cooling Solutions: Some designs incorporate cooling channels directly into the battery architecture, improving overall efficiency.

- AI and Machine Learning: These technologies are being explored to predict temperature fluctuations and optimize cooling strategies dynamically.

Chart: Innovations in Thermal Management

| Innovation | Description |

|---|---|

| Smart Systems | Real-time monitoring with automated adjustments |

| Advanced Materials | New materials for better insulation/dissipation |

| Integrated Solutions | Cooling channels built into battery design |

| AI & Machine Learning | Predictive analytics for dynamic optimization |

Industrial News

Recent advancements in battery technology have highlighted the importance of effective thermal management systems, especially as electric vehicles become more prevalent. Manufacturers are focusing on developing integrated solutions that enhance safety while optimizing performance through innovative cooling technologies. As demand increases, these advancements aim to improve battery longevity and reliability across various applications.

Redway Power Insights

“Thermal management is a critical aspect of modern battery technology,” states Redway Power’s expert team. “By investing in advanced cooling solutions and understanding how different chemistries respond to temperature changes, manufacturers can significantly enhance both safety and performance.”

FAQ Section

Q: Why is thermal runaway a concern for lithium-ion batteries?

A: Thermal runaway occurs when a battery overheats uncontrollably, leading to fire or explosion; effective thermal management helps prevent this.Q: How often should I check my battery’s temperature?

A: Regular monitoring is recommended, especially during heavy use or charging cycles; using smart systems can automate this process.Q: Can I improve my existing battery system’s thermal management?

A: Yes, retrofitting with better insulation, adding active cooling systems, or integrating smart monitoring can enhance performance.