- Forklift Lithium Battery

-

48V

- 48V 210Ah

- 48V 300Ah

- 48V 420Ah (949 x 349 x 569 mm)

- 48V 420Ah (950 x 421 x 450 mm)

- 48V 456Ah

- 48V 460Ah (830 x 630 x 590 mm)

- 48V 460Ah (950 x 421 x 450 mm)

- 48V 460Ah (800 x 630 x 600 mm)

- 48V 460Ah (820 x 660 x 470 mm)

- 48V 500Ah

- 48V 560Ah (810 x 630 x 600 mm)

- 48V 560Ah (950 x 592 x 450 mm)

- 48V 600Ah

- 48V 630Ah

-

48V

- Lithium Golf Cart Battery

- 12V Lithium Battery

12V 150Ah Lithium RV Battery

Bluetooth App | BCI Group 31

LiFePO4 Lithium

Discharge Temperature -20°C ~ 65°C

Fast Charger 14.6V 50A

Solar MPPT Charging - 24V Lithium Battery

- 36V Lithium Battery

- 48V Lithium Battery

-

48V LiFePO4 Battery

- 48V 50Ah

- 48V 50Ah (for Golf Carts)

- 48V 60Ah (8D)

- 48V 100Ah (8D)

- 48V 100Ah

- 48V 100Ah (Discharge 100A for Golf Carts)

- 48V 100Ah (Discharge 150A for Golf Carts)

- 48V 100Ah (Discharge 200A for Golf Carts)

- 48V 150Ah (for Golf Carts)

- 48V 160Ah (Discharge 100A for Golf Carts)

- 48V 160Ah (Discharge 160A for Golf Carts)

-

48V LiFePO4 Battery

- 60V Lithium Battery

-

60V LiFePO4 Battery

- 60V 20Ah

- 60V 30Ah

- 60V 50Ah

- 60V 50Ah (Small Size / Side Terminal)

- 60V 100Ah (for Electric Motocycle, Electric Scooter, LSV, AGV)

- 60V 100Ah (for Forklift, AGV, Electric Scooter, Sweeper)

- 60V 150Ah (E-Motocycle / E-Scooter / E-Tricycle / Tour LSV)

- 60V 200Ah (for Forklift, AGV, Electric Scooter, Sweeper)

-

60V LiFePO4 Battery

- 72V~96V Lithium Battery

- Rack-mounted Lithium Battery

- E-Bike Battery

- All-in-One Home-ESS

- Wall-mount Battery ESS

-

Home-ESS Lithium Battery PowerWall

- 24V 100Ah 2.4kWh PW24100-S PowerWall

- 48V 50Ah 2.4kWh PW4850-S PowerWall

- 48V 50Ah 2.56kWh PW5150-S PowerWall

- 48V 100Ah 5.12kWh PW51100-F PowerWall (IP65)

- 48V 100Ah 5.12kWh PW51100-S PowerWall

- 48V 100Ah 5.12kWh PW51100-H PowerWall

- 48V 200Ah 10kWh PW51200-H PowerWall

- 48V 300Ah 15kWh PW51300-H PowerWall

PowerWall 51.2V 100Ah LiFePO4 Lithium Battery

Highly popular in Asia and Eastern Europe.

CE Certification | Home-ESS -

Home-ESS Lithium Battery PowerWall

- Portable Power Stations

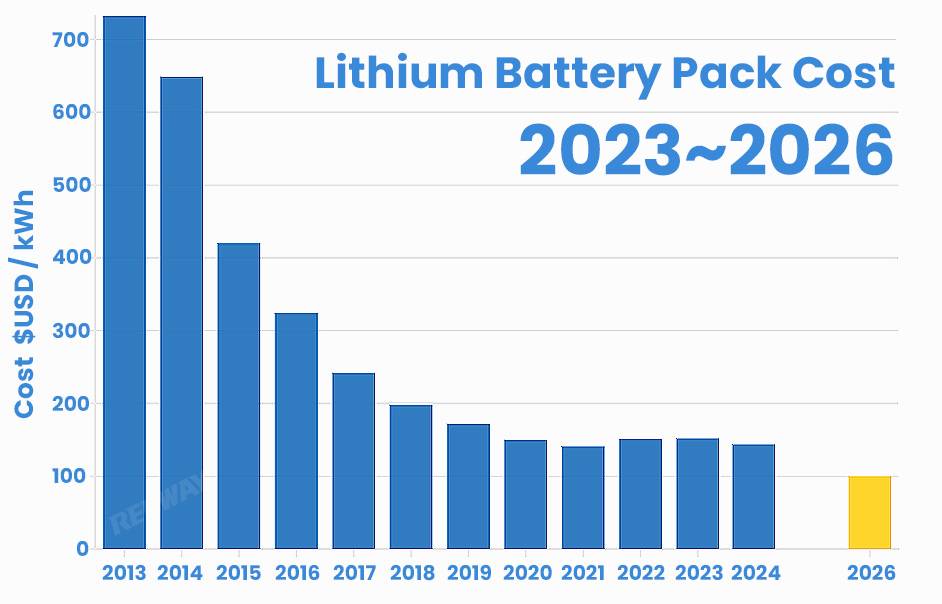

What Is the Cost of Lithium-Ion Batteries in 2024?

In 2024, the average cost of lithium-ion batteries has significantly decreased, with prices reaching around $115 per kilowatt-hour (kWh). This decline is attributed to various market dynamics, including increased manufacturing capacity and reduced raw material costs, making these batteries more accessible for electric vehicles and energy storage solutions.

What is the current average cost of lithium-ion batteries in 2024?

As of 2024, the average cost of lithium-ion batteries is approximately $115 per kWh. This represents a notable decrease from previous years, driven by advancements in technology and manufacturing efficiencies. The price for electric vehicle (EV) batteries has also fallen below $100 per kWh for the first time, marking a significant milestone in the industry.Chart: Average Lithium-Ion Battery Prices Over Recent Years

| Year | Average Price per kWh |

|---|---|

| 2020 | $137 |

| 2021 | $129 |

| 2022 | $144 |

| 2023 | $139 |

| 2024 | $115 |

How do lithium-ion battery prices compare to previous years?

Lithium-ion battery prices have seen a dramatic decline over recent years. In 2020, prices were around $137 per kWh, dropping to approximately $115 per kWh in 2024. This trend reflects a broader shift towards more affordable energy storage solutions, particularly as competition increases among manufacturers.

What factors are driving the decline in lithium-ion battery costs?

Several key factors contribute to the declining costs of lithium-ion batteries:

- Increased Manufacturing Capacity: Overcapacity in production has led to lower prices due to competition.

- Economies of Scale: As production volumes increase, per-unit costs decrease.

- Raw Material Prices: A reduction in the costs of essential materials like lithium and cobalt has directly impacted overall battery pricing.

- Technological Advancements: Innovations in manufacturing processes have improved efficiency and reduced waste.

Chart: Key Factors Influencing Lithium-Ion Battery Prices

| Factor | Impact on Prices |

|---|---|

| Manufacturing Capacity | Decreases due to competition |

| Economies of Scale | Lowers per-unit costs |

| Raw Material Costs | Directly affects overall pricing |

| Technological Innovations | Enhances efficiency and reduces costs |

How does the composition of lithium-ion batteries affect pricing?

The composition of lithium-ion batteries plays a crucial role in determining their cost. The cathode material typically accounts for over half of the total battery cost. For instance:

- Nickel Manganese Cobalt (NMC): More expensive but offers higher energy density.

- Lithium Iron Phosphate (LFP): Generally cheaper due to abundant materials, making it a popular alternative for certain applications.

What implications do lower battery prices have on the electric vehicle market?

Lower battery prices significantly impact the electric vehicle market by reducing overall vehicle costs. As battery packs become more affordable, manufacturers can offer competitive pricing for EVs, increasing consumer adoption. In fact, it is projected that with continued price reductions, EVs will reach parity with internal combustion engine vehicles sooner than anticipated.

Can we expect further price reductions in the future?

Yes, further price reductions are expected as advancements in technology continue and new manufacturing processes are developed. Analysts predict that average prices could drop to around $99 per kWh by 2025 as economies of scale and improvements in raw material sourcing come into play.

What alternatives to traditional lithium-ion batteries exist?

Alternatives such as Lithium Iron Phosphate (LFP) and Sodium-Ion batteries are being explored as substitutes for traditional lithium-ion technologies. These alternatives often offer different benefits such as enhanced safety or lower costs but may come with trade-offs regarding energy density or performance.Redway Power, which specializes in innovative energy storage solutions, provides excellent alternatives for customers seeking different chemistry options.

Tips for Battery Wholesale Buyers

When considering purchases from reliable manufacturers like Redway Power, keep these key points in mind:

- Assess manufacturer experience and reputation.

- Request samples or prototypes before large orders.

- Ensure compliance with international safety standards.

- Discuss customization options based on specific needs.

- Maintain clear communication channels for ongoing support.

With over 13 years of experience as a well-known lithium battery manufacturer, Redway Power is an excellent choice for wholesale buyers looking for high-quality products.

Redway Power Expert Views

“Understanding the dynamics behind lithium-ion battery pricing is crucial for making informed purchasing decisions,” states a representative from Redway Power. “As we continue to innovate and improve our manufacturing processes, we aim to provide our clients with cost-effective solutions that meet their energy storage needs.”

Conclusion

The popularity of lithium-ion batteries, used in devices from smartphones to electric vehicles, has led to decreased costs due to technological advancements. Anticipating exponential demand by 2024, innovations may further lower costs and enhance performance. Proper disposal and recycling are crucial to prevent environmental harm, emphasizing the need for efficient recycling methods. Balancing cost efficiency and environmental impact, investing in lithium-ion technology proves promising for individuals and businesses.

FAQs

Why choose LiFePO4 over traditional lithium-ion batteries?

How does Ionic Deep Cycle compare to lead-acid Ah ratings?

What advantages do Ionic Deep Cycle Batteries offer?

Why select Ionic lithium-ion Deep Cycle batteries?

More MOQs

How much does a lithium-ion battery cost?

The cost of a lithium-ion battery varies depending on factors such as size, capacity, quality, and market conditions. As of recent years, the cost per kilowatt-hour (kWh) for lithium-ion batteries has been steadily decreasing due to advancements in technology, economies of scale, and increased competition in the market.

What is the cost of a lithium-ion battery in an EV?

The cost of a lithium-ion battery in an electric vehicle (EV) constitutes a significant portion of the vehicle’s overall cost. On average, the battery pack accounts for around 20% to 40% of the total cost of an EV, depending on factors such as battery size, energy capacity, and vehicle model.

Are lithium battery prices dropping?

Yes, lithium battery prices have been steadily declining in recent years due to various factors such as technological advancements, economies of scale, and increased competition among battery manufacturers. This trend is expected to continue as battery technology improves and production processes become more efficient.

What is the future price of lithium?

The future price of lithium depends on factors such as demand from industries like electric vehicles and energy storage, supply dynamics, technological advancements, and government policies. While short-term fluctuations may occur, the long-term trend for lithium prices is influenced by these factors and is subject to change.

What is the lithium forecast for 2025?

Forecasts for lithium prices in 2025 vary depending on market conditions, demand projections, and supply dynamics. While some analysts predict stable or moderately increasing prices due to growing demand for electric vehicles and energy storage, others anticipate price fluctuations influenced by factors such as new production capacity and technological advancements.

What is the most expensive part of a lithium-ion battery?

The most expensive part of a lithium-ion battery is typically the battery cells themselves, which account for a significant portion of the total cost. Other factors contributing to the cost include the battery management system (BMS), thermal management components, housing, and assembly.

Are lithium-ion batteries getting cheaper?

Yes, lithium-ion batteries are getting cheaper over time due to advancements in technology, economies of scale, and increased production efficiency. As demand for electric vehicles and energy storage systems grows, manufacturers are investing in research and development to reduce costs and improve performance.

Why are lithium batteries so expensive right now?

Lithium batteries can be expensive due to several factors, including the cost of raw materials such as lithium, cobalt, and nickel, as well as manufacturing processes, quality control standards, and market demand. Additionally, fluctuations in commodity prices and supply chain disruptions can impact the cost of lithium batteries. However, ongoing technological advancements and increased production capacity are helping to reduce costs over time.