- Lithium Golf Cart Battery

- Forklift Lithium Battery

-

48V

- 48V 210Ah

- 48V 300Ah

- 48V 420Ah (949 x 349 x 569 mm)

- 48V 420Ah (950 x 421 x 450 mm)

- 48V 456Ah

- 48V 460Ah (830 x 630 x 590 mm)

- 48V 460Ah (950 x 421 x 450 mm)

- 48V 460Ah (800 x 630 x 600 mm)

- 48V 460Ah (820 x 660 x 470 mm)

- 48V 500Ah

- 48V 560Ah (810 x 630 x 600 mm)

- 48V 560Ah (950 x 592 x 450 mm)

- 48V 600Ah

- 48V 630Ah

-

48V

- 12V Lithium Battery

12V 150Ah Lithium RV Battery

Bluetooth App | BCI Group 31

LiFePO4 Lithium

Discharge Temperature -20°C ~ 65°C

Fast Charger 14.6V 50A

Solar MPPT Charging - 24V Lithium Battery

- 36V Lithium Battery

- 48V Lithium Battery

-

48V LiFePO4 Battery

- 48V 50Ah

- 48V 50Ah (for Golf Carts)

- 48V 60Ah (8D)

- 48V 100Ah (8D)

- 48V 100Ah

- 48V 100Ah (Discharge 100A for Golf Carts)

- 48V 100Ah (Discharge 150A for Golf Carts)

- 48V 100Ah (Discharge 200A for Golf Carts)

- 48V 150Ah (for Golf Carts)

- 48V 160Ah (Discharge 100A for Golf Carts)

- 48V 160Ah (Discharge 160A for Golf Carts)

-

48V LiFePO4 Battery

- 60V Lithium Battery

-

60V LiFePO4 Battery

- 60V 20Ah

- 60V 30Ah

- 60V 50Ah

- 60V 50Ah (Small Size / Side Terminal)

- 60V 100Ah (for Electric Motocycle, Electric Scooter, LSV, AGV)

- 60V 100Ah (for Forklift, AGV, Electric Scooter, Sweeper)

- 60V 150Ah (E-Motocycle / E-Scooter / E-Tricycle / Tour LSV)

- 60V 200Ah (for Forklift, AGV, Electric Scooter, Sweeper)

-

60V LiFePO4 Battery

- 72V~96V Lithium Battery

- Rack-mounted Lithium Battery

- E-Bike Battery

- All-in-One Home-ESS

- Wall-mount Battery ESS

-

Home-ESS Lithium Battery PowerWall

- 24V 100Ah 2.4kWh PW24100-S PowerWall

- 48V 50Ah 2.4kWh PW4850-S PowerWall

- 48V 50Ah 2.56kWh PW5150-S PowerWall

- 48V 100Ah 5.12kWh PW51100-F PowerWall (IP65)

- 48V 100Ah 5.12kWh PW51100-S PowerWall

- 48V 100Ah 5.12kWh PW51100-H PowerWall

- 48V 200Ah 10kWh PW51200-H PowerWall

- 48V 300Ah 15kWh PW51300-H PowerWall

PowerWall 51.2V 100Ah LiFePO4 Lithium Battery

Highly popular in Asia and Eastern Europe.

CE Certification | Home-ESS -

Home-ESS Lithium Battery PowerWall

- Portable Power Stations

What Are the 3 Main Components of Battery Cells?

The three main components of battery cells are the anode, cathode, and electrolyte. These elements work together to store and release electrical energy through electrochemical reactions. Understanding these components is crucial for grasping how batteries function in various applications.

What Are the Three Main Components of Battery Cells?

The primary components of battery cells include:

- Anode: The negative electrode where oxidation occurs during discharge.

- Cathode: The positive electrode that undergoes reduction during discharge.

- Electrolyte: A medium that facilitates ion movement between the anode and cathode while preventing direct electron flow.

These components are essential for the battery’s ability to store and release energy effectively.Chart: Key Components of a Battery

| Component | Description |

|---|---|

| Anode | Negative electrode where oxidation occurs |

| Cathode | Positive electrode where reduction occurs |

| Electrolyte | Medium for ion transport between electrodes |

How Do Each of These Components Function in a Battery?

Each component plays a vital role in battery operation:

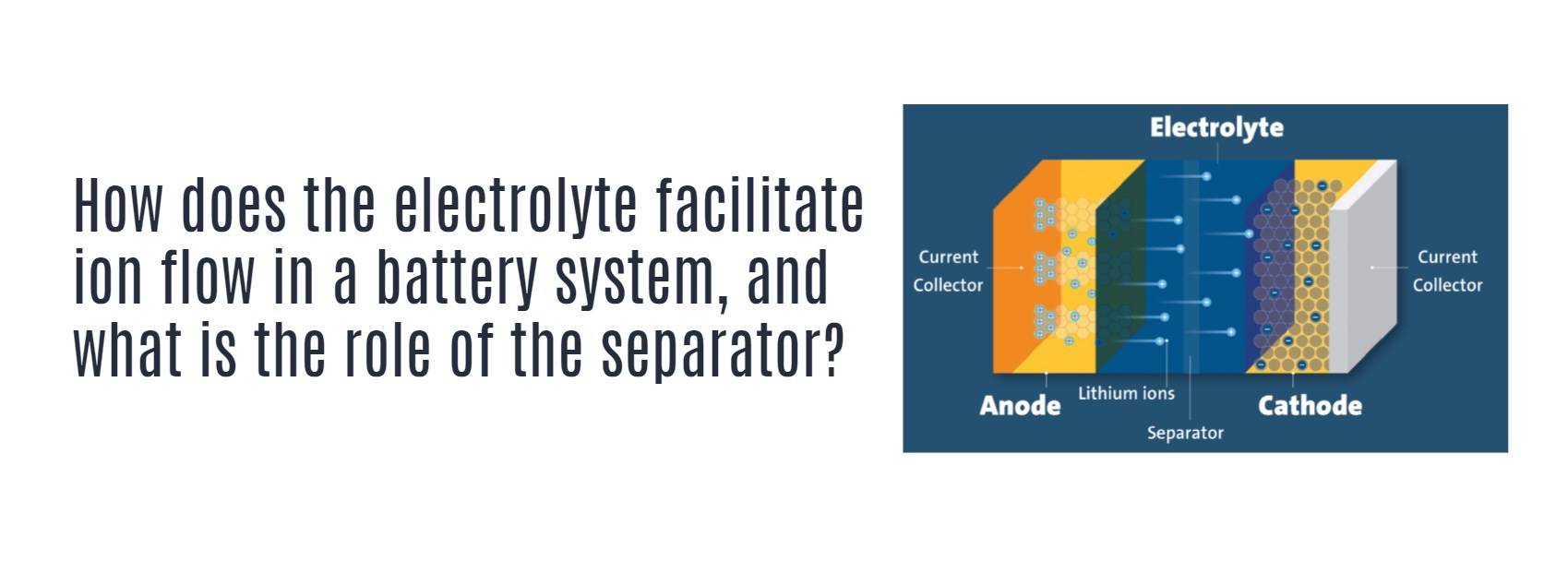

- Anode: During discharge, lithium ions move from the anode through the electrolyte to the cathode, while electrons flow through an external circuit, providing power to connected devices.

- Cathode: The cathode accepts electrons from the external circuit, facilitating further chemical reactions that allow lithium ions to intercalate into its structure.

- Electrolyte: The electrolyte allows lithium ions to pass between the anode and cathode while acting as an insulator for electrons, ensuring that current flows through the external circuit instead.

What Is the Role of the Anode in Battery Operation?

The anode is crucial for initiating the battery’s discharge process. It typically consists of materials like graphite or lithium titanate, which can store lithium ions during charging. When discharging, these ions move toward the cathode, releasing energy in the form of electrons that flow through an external circuit.

How Does the Cathode Contribute to Energy Storage?

The cathode serves as the site for accepting lithium ions during discharge and storing them during charging. Common materials used for cathodes include lithium cobalt oxide (LiCoO2) and lithium iron phosphate (LiFePO4). The efficiency and capacity of a battery are significantly influenced by the cathode material used.

See also Why Understanding Watt-Hour Ratings is Critical for the Transportation of Lithium Batteries

What Is the Function of the Electrolyte in a Battery?

The electrolyte facilitates ion transport between the anode and cathode while preventing direct electron flow. It can be liquid, gel, or solid, depending on battery design. The choice of electrolyte affects battery performance, including conductivity, stability, and safety.

How Do These Components Work Together to Power Devices?

When a battery is connected to a device:

- Discharge Process: Lithium ions flow from the anode through the electrolyte to the cathode, while electrons travel through an external circuit to provide power.

- Charge Process: When recharging, an external power source applies voltage, reversing ion flow back to the anode, restoring energy.

This cycle continues until either electrode material is depleted.

What Are Some Common Applications for Different Types of Batteries?

Different types of batteries serve various applications based on their components:

- Lithium-Ion Batteries: Used in smartphones, laptops, and electric vehicles due to their high energy density and rechargeability.

- Lead-Acid Batteries: Commonly found in automotive applications and backup power systems due to their reliability.

- Nickel-Metal Hydride (NiMH) Batteries: Often used in hybrid vehicles and consumer electronics.

These applications leverage specific characteristics derived from their component materials.

Tips for Battery Wholesale Buyers

When selecting batteries for OEM applications, consider:

- Performance Requirements: Assess energy density, cycle life, and discharge rates needed for your application.

- Cost Efficiency: Evaluate both initial costs and long-term savings associated with battery longevity and maintenance.

- Supplier Reliability: Partner with established manufacturers like Redway Power, which offers high-quality lithium battery solutions backed by over 13 years of experience.

By understanding these factors, buyers can make informed decisions that enhance their product offerings while optimizing performance.

Redway Power Expert Views

“Understanding battery components is essential for anyone involved in technology development,” states an expert from Redway Power. “The right combination of materials can significantly impact performance, safety, and longevity.”In conclusion, knowing about the three main components—anode, cathode, and electrolyte—provides valuable insight into how batteries function. This knowledge is crucial for selecting appropriate batteries for various applications across industries.

FAQS

Why EMS is Essential in BESS

An Energy Management System (EMS) is crucial in a Battery Energy Storage System (BESS). It consists of sensors, meters, and controllers that track energy metrics in real-time. The EMS enables seamless communication between its digital directives and the BESS’s physical operations, ensuring precise energy management. This integration optimizes the performance of the BESS, allowing for cost-effective and efficient operation in coordination with other generation sources.