- Forklift Lithium Battery

-

48V

- 48V 210Ah

- 48V 300Ah

- 48V 420Ah (949 x 349 x 569 mm)

- 48V 420Ah (950 x 421 x 450 mm)

- 48V 456Ah

- 48V 460Ah (830 x 630 x 590 mm)

- 48V 460Ah (950 x 421 x 450 mm)

- 48V 460Ah (800 x 630 x 600 mm)

- 48V 460Ah (820 x 660 x 470 mm)

- 48V 500Ah

- 48V 560Ah (810 x 630 x 600 mm)

- 48V 560Ah (950 x 592 x 450 mm)

- 48V 600Ah

- 48V 630Ah

-

48V

- Lithium Golf Cart Battery

- 12V Lithium Battery

12V 150Ah Lithium RV Battery

Bluetooth App | BCI Group 31

LiFePO4 Lithium

Discharge Temperature -20°C ~ 65°C

Fast Charger 14.6V 50A

Solar MPPT Charging - 24V Lithium Battery

- 36V Lithium Battery

- 48V Lithium Battery

-

48V LiFePO4 Battery

- 48V 50Ah

- 48V 50Ah (for Golf Carts)

- 48V 60Ah (8D)

- 48V 100Ah (8D)

- 48V 100Ah

- 48V 100Ah (Discharge 100A for Golf Carts)

- 48V 100Ah (Discharge 150A for Golf Carts)

- 48V 100Ah (Discharge 200A for Golf Carts)

- 48V 150Ah (for Golf Carts)

- 48V 160Ah (Discharge 100A for Golf Carts)

- 48V 160Ah (Discharge 160A for Golf Carts)

-

48V LiFePO4 Battery

- 60V Lithium Battery

-

60V LiFePO4 Battery

- 60V 20Ah

- 60V 30Ah

- 60V 50Ah

- 60V 50Ah (Small Size / Side Terminal)

- 60V 100Ah (for Electric Motocycle, Electric Scooter, LSV, AGV)

- 60V 100Ah (for Forklift, AGV, Electric Scooter, Sweeper)

- 60V 150Ah (E-Motocycle / E-Scooter / E-Tricycle / Tour LSV)

- 60V 200Ah (for Forklift, AGV, Electric Scooter, Sweeper)

-

60V LiFePO4 Battery

- 72V~96V Lithium Battery

- Rack-mounted Lithium Battery

- E-Bike Battery

- All-in-One Home-ESS

- Wall-mount Battery ESS

-

Home-ESS Lithium Battery PowerWall

- 24V 100Ah 2.4kWh PW24100-S PowerWall

- 48V 50Ah 2.4kWh PW4850-S PowerWall

- 48V 50Ah 2.56kWh PW5150-S PowerWall

- 48V 100Ah 5.12kWh PW51100-F PowerWall (IP65)

- 48V 100Ah 5.12kWh PW51100-S PowerWall

- 48V 100Ah 5.12kWh PW51100-H PowerWall

- 48V 200Ah 10kWh PW51200-H PowerWall

- 48V 300Ah 15kWh PW51300-H PowerWall

PowerWall 51.2V 100Ah LiFePO4 Lithium Battery

Highly popular in Asia and Eastern Europe.

CE Certification | Home-ESS -

Home-ESS Lithium Battery PowerWall

- Portable Power Stations

How to Prevent Battery Terminal Corrosion: Causes and Solutions

Battery terminal corrosion is a common issue that can lead to poor electrical connectivity and reduced battery life. Understanding the causes of corrosion and implementing preventive measures can help maintain your battery’s performance. This article explores the reasons behind battery terminal corrosion and offers effective solutions to prevent it.

What Causes Battery Terminal Corrosion?

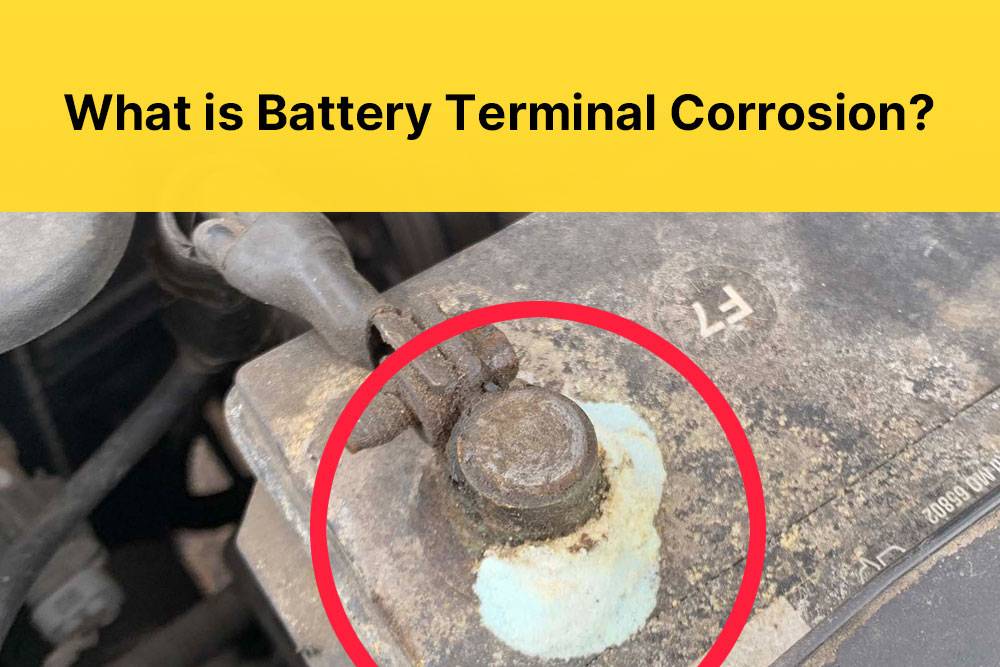

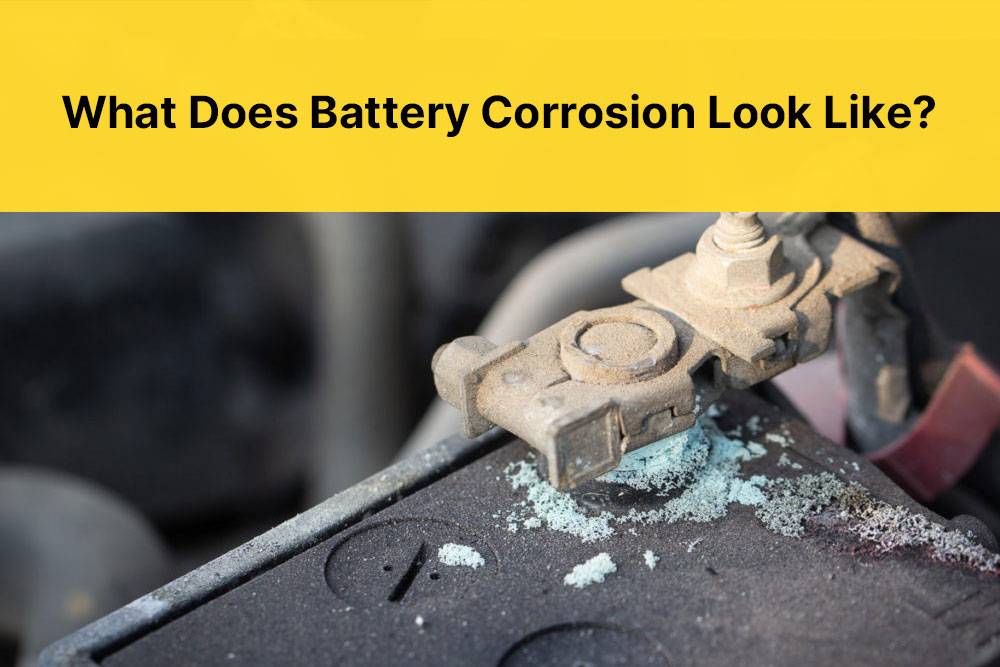

Battery terminal corrosion typically appears as a white, blue, or green powder around the terminals and can significantly affect the performance of your vehicle’s electrical system. The primary causes include:

- Hydrogen Gas Release: During charging, batteries release hydrogen gas, which can react with moisture and salts in the environment, leading to corrosion.

- Overcharging: Overcharging a battery raises its temperature and pressure, causing electrolyte leakage that contributes to corrosion.

- Electrolyte Leaks: Damage to the battery casing can lead to leaks of corrosive electrolyte fluid, which accelerates corrosion.

- Bimetallic Contact: Corrosion can also occur due to chemical reactions between different metals used in battery terminals and connectors.

Chart: Common Causes of Battery Terminal Corrosion

| Cause | Description |

|---|---|

| Hydrogen Gas Release | Gas reacts with moisture and salts in the air |

| Overcharging | Increased temperature leads to electrolyte leakage |

| Electrolyte Leaks | Damage to casing allows corrosive fluid to escape |

| Bimetallic Contact | Chemical reactions between different metals |

How Can You Prevent Battery Terminal Corrosion?

Preventing battery terminal corrosion involves regular maintenance and protective measures. Here are some effective strategies:

- Regular Cleaning: Clean terminals regularly using a mixture of baking soda and water to neutralize acid buildup.

- Use Protective Coatings: Apply dielectric grease or battery terminal protectors after cleaning to create a barrier against moisture and contaminants.

- Check Battery Levels: For refillable batteries, ensure electrolyte levels are topped up with distilled water to prevent overfilling or leaking.

- Monitor Charging Practices: Avoid overcharging by using a quality charger with an automatic shutoff feature.

Chart: Preventive Measures for Battery Terminal Corrosion

| Preventive Measure | Description |

|---|---|

| Regular Cleaning | Use baking soda solution to neutralize acid buildup |

| Protective Coatings | Apply dielectric grease or protectors |

| Check Battery Levels | Maintain proper electrolyte levels |

| Monitor Charging Practices | Use chargers with automatic shutoff features |

Why Is It Important to Address Battery Terminal Corrosion?

Addressing battery terminal corrosion is crucial for several reasons:

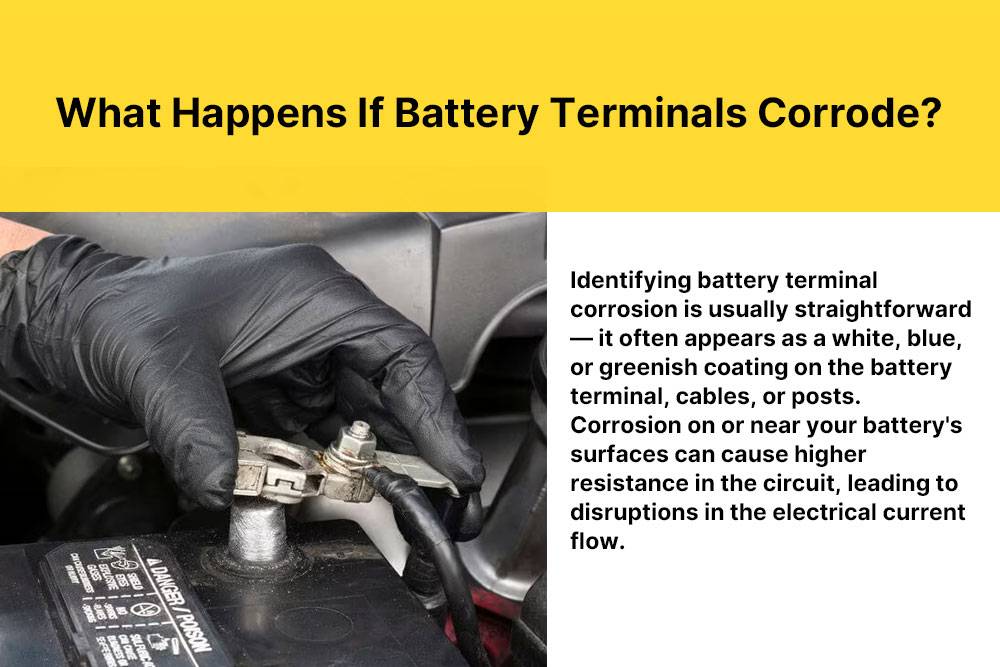

- Improved Electrical Conductivity: Corrosion increases resistance, leading to poor electrical connections that can hinder vehicle performance.

- Extended Battery Life: Regular maintenance prevents damage that could shorten the lifespan of your battery.

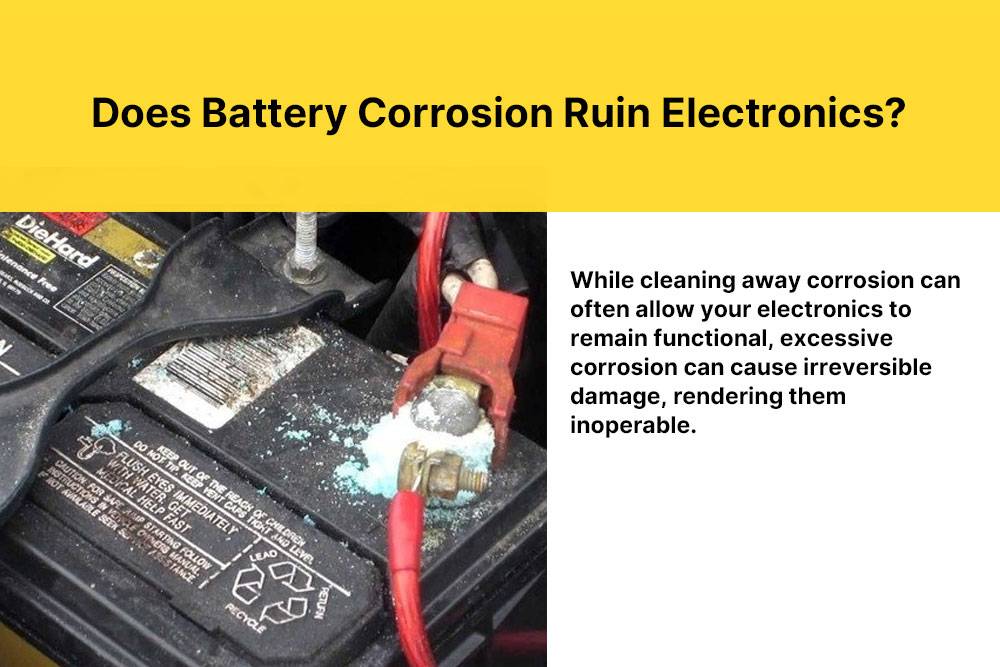

- Safety Concerns: Corroded terminals can lead to sparks or short circuits, posing fire hazards.

What Are the Signs of Battery Terminal Corrosion?

Recognizing the signs of battery terminal corrosion early can help mitigate issues before they escalate. Common indicators include:

- Visible Buildup: A white, blue, or green powdery substance around the terminals.

- Difficulty Starting: Increased resistance may lead to trouble starting the vehicle.

- Frequent Electrical Issues: Flickering lights or malfunctioning electronics can indicate poor connections due to corrosion.

Chart: Signs of Battery Terminal Corrosion

| Sign | Description |

|---|---|

| Visible Buildup | Powdery substance around terminals |

| Difficulty Starting | Trouble starting the vehicle |

| Frequent Electrical Issues | Flickering lights or malfunctioning electronics |

How Do You Clean Corroded Battery Terminals?

Cleaning corroded battery terminals is a straightforward process but requires safety precautions. Follow these steps:

- Safety First: Wear gloves and eye protection before handling corroded materials.

- Disconnect the Battery: Start by disconnecting the negative terminal followed by the positive terminal.

- Prepare Cleaning Solution: Mix baking soda with water (1 tablespoon of baking soda per cup of water).

- Scrub the Terminals: Use a wire brush or toothbrush dipped in the solution to scrub away corrosion gently.

- Rinse and Dry: Rinse the terminals with clean water and dry them thoroughly before reconnecting.

Industrial News

Recent advancements in battery technology have led manufacturers to develop more robust coatings and protective solutions for battery terminals. Innovations focus on enhancing corrosion resistance while maintaining optimal conductivity. These developments are crucial as electric vehicles become more prevalent, requiring reliable power sources for extended use.

Redway Power Expert Views

“Preventing battery terminal corrosion is essential for maintaining optimal vehicle performance,” states an expert from Redway Power. “Regular maintenance not only extends battery life but also ensures safety by reducing the risk of electrical failures.”

FAQ Section

What is battery terminal corrosion?

Battery terminal corrosion is a chemical reaction that occurs at the battery terminals, resulting in a buildup of white, blue, or green powder that impairs electrical conductivity.How often should I clean my battery terminals?

It’s advisable to check and clean your battery terminals every few months or whenever you notice signs of corrosion.Can I use regular grease on battery terminals?

No, it’s better to use dielectric grease specifically designed for batteries as it prevents moisture without attracting dirt.