- Forklift Lithium Battery

-

48V

- 48V 210Ah

- 48V 300Ah

- 48V 420Ah (949 x 349 x 569 mm)

- 48V 420Ah (950 x 421 x 450 mm)

- 48V 456Ah

- 48V 460Ah (830 x 630 x 590 mm)

- 48V 460Ah (950 x 421 x 450 mm)

- 48V 460Ah (800 x 630 x 600 mm)

- 48V 460Ah (820 x 660 x 470 mm)

- 48V 500Ah

- 48V 560Ah (810 x 630 x 600 mm)

- 48V 560Ah (950 x 592 x 450 mm)

- 48V 600Ah

- 48V 630Ah

-

48V

- Lithium Golf Cart Battery

- 12V Lithium Battery

12V 150Ah Lithium RV Battery

Bluetooth App | BCI Group 31

LiFePO4 Lithium

Discharge Temperature -20°C ~ 65°C

Fast Charger 14.6V 50A

Solar MPPT Charging - 24V Lithium Battery

- 36V Lithium Battery

- 48V Lithium Battery

-

48V LiFePO4 Battery

- 48V 50Ah

- 48V 50Ah (for Golf Carts)

- 48V 60Ah (8D)

- 48V 100Ah (8D)

- 48V 100Ah

- 48V 100Ah (Discharge 100A for Golf Carts)

- 48V 100Ah (Discharge 150A for Golf Carts)

- 48V 100Ah (Discharge 200A for Golf Carts)

- 48V 150Ah (for Golf Carts)

- 48V 160Ah (Discharge 100A for Golf Carts)

- 48V 160Ah (Discharge 160A for Golf Carts)

-

48V LiFePO4 Battery

- 60V Lithium Battery

-

60V LiFePO4 Battery

- 60V 20Ah

- 60V 30Ah

- 60V 50Ah

- 60V 50Ah (Small Size / Side Terminal)

- 60V 100Ah (for Electric Motocycle, Electric Scooter, LSV, AGV)

- 60V 100Ah (for Forklift, AGV, Electric Scooter, Sweeper)

- 60V 150Ah (E-Motocycle / E-Scooter / E-Tricycle / Tour LSV)

- 60V 200Ah (for Forklift, AGV, Electric Scooter, Sweeper)

-

60V LiFePO4 Battery

- 72V~96V Lithium Battery

- Rack-mounted Lithium Battery

- E-Bike Battery

- All-in-One Home-ESS

- Wall-mount Battery ESS

-

Home-ESS Lithium Battery PowerWall

- 24V 100Ah 2.4kWh PW24100-S PowerWall

- 48V 50Ah 2.4kWh PW4850-S PowerWall

- 48V 50Ah 2.56kWh PW5150-S PowerWall

- 48V 100Ah 5.12kWh PW51100-F PowerWall (IP65)

- 48V 100Ah 5.12kWh PW51100-S PowerWall

- 48V 100Ah 5.12kWh PW51100-H PowerWall

- 48V 200Ah 10kWh PW51200-H PowerWall

- 48V 300Ah 15kWh PW51300-H PowerWall

PowerWall 51.2V 100Ah LiFePO4 Lithium Battery

Highly popular in Asia and Eastern Europe.

CE Certification | Home-ESS -

Home-ESS Lithium Battery PowerWall

- Portable Power Stations

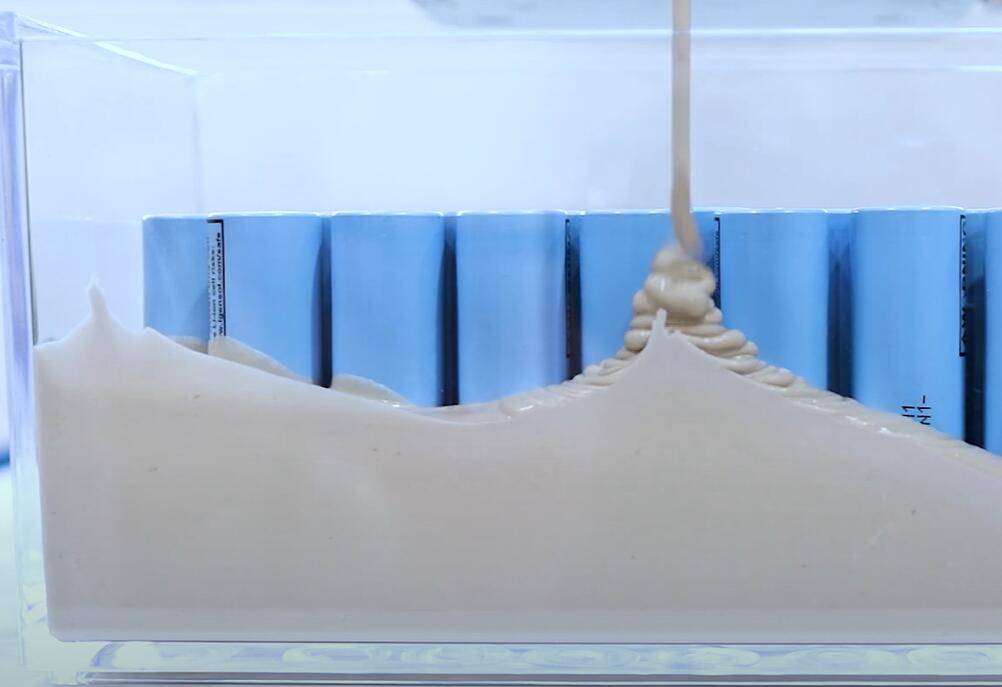

How is Potting Glue Used in Battery Potting and Encapsulation?

Potting glue plays a crucial role in battery potting and encapsulation, enhancing the performance and longevity of batteries, especially lithium-ion types. By filling voids around battery components, potting glue protects against environmental factors, mechanical stresses, and thermal fluctuations. This ensures reliable operation across various applications.

What is Battery Potting and How Does it Work?

Battery potting is the process of filling spaces around battery components with a protective material, typically an epoxy or polyurethane resin. This process provides mechanical support, moisture resistance, and thermal insulation. During potting, the battery cells are placed in a mold, and the potting compound is poured in to encapsulate them fully or partially.Chart: Battery Potting Process Steps

| Step | Description |

|---|---|

| 1. Preparation | Assemble battery components and connections. |

| 2. Molding | Place components in a mold designed for potting. |

| 3. Application | Pour potting compound into the mold. |

| 4. Curing | Allow the compound to cure as per specifications. |

How Does Potting Glue Enhance Battery Performance?

Potting glue enhances battery performance by providing several protective features:

- Mechanical Reinforcement: It helps secure battery cells in place, reducing vibration and shock impacts.

- Moisture Barrier: The glue prevents moisture ingress, which can lead to corrosion or short circuits.

- Thermal Insulation: It aids in heat dissipation during operation, maintaining optimal temperatures.

These factors contribute to improved reliability and lifespan of batteries.

What Are the Key Benefits of Using Potting Glue in Batteries?

Using potting glue offers numerous benefits:

- Protection from Environmental Factors: Shields batteries from dust, moisture, and chemical exposure.

- Enhanced Durability: Increases mechanical strength against shocks and vibrations.

- Thermal Management: Some potting materials have good thermal conductivity to manage heat effectively.

Chart: Benefits of Potting Glue

| Benefit | Description |

|---|---|

| Environmental Protection | Shields against moisture and contaminants. |

| Mechanical Strength | Provides reinforcement against shocks. |

| Thermal Management | Aids in heat dissipation during operation. |

How Does Encapsulation Differ from Potting?

Encapsulation involves fully coating a battery or its components with a protective layer, while potting focuses on filling gaps around the components. Encapsulation provides a complete seal that can prevent the release of harmful substances during battery failure, whereas potting primarily enhances structural integrity.

What Types of Materials Are Used in Battery Potting?

Common materials used for battery potting include:

- Epoxy Resins: Known for excellent adhesion and thermal stability.

- Polyurethane: Offers good flexibility and resistance to environmental degradation.

- Silicone: Provides high elasticity and excellent temperature resistance.

Choosing the right material depends on specific application requirements such as operating conditions and environmental exposure.

Can Potting Glue Help with Thermal Management?

Yes, potting glue can significantly assist with thermal management by dissipating heat generated during battery operation. Some advanced formulations include thermally conductive additives that enhance heat transfer away from critical components, preventing overheating and improving overall efficiency.

What Are the Common Applications for Battery Potting and Encapsulation?

Battery potting and encapsulation are widely used across various industries:

- Consumer Electronics: Smartphones, laptops, tablets.

- Electric Vehicles (EVs): Ensures safety and reliability under varying conditions.

- Renewable Energy Systems: Protects batteries used in solar power storage.

These applications benefit from enhanced durability and performance provided by potting and encapsulation techniques.

Tips for Battery Wholesale Buyers

When purchasing batteries wholesale or making OEM orders, it’s crucial to choose a reliable manufacturer like Redway Power, which has over thirteen years of experience in lithium battery manufacturing. They offer various lithium-ion products that serve as excellent alternatives to lead-acid batteries. To make OEM orders effectively:

- Research potential suppliers thoroughly.

- Request samples to evaluate quality.

- Discuss customization options based on your needs.

- Ensure clear communication regarding specifications and delivery timelines.

Redway Power Expert Views

“Potting glue application is vital for ensuring the longevity and reliability of lithium batteries,” states an expert from Redway Power. “By protecting against environmental hazards while enhancing thermal management, our innovative solutions are designed to meet the evolving demands of modern battery applications.”

FAQ Section

- What is battery potting?

Battery potting involves filling voids around battery components with protective materials like epoxy or polyurethane to enhance durability. - How does potting glue protect batteries?

It protects against moisture, vibration, thermal fluctuations, and environmental contaminants that could damage battery performance. - What materials are commonly used for battery potting?

Common materials include epoxy resins, polyurethane, and silicone due to their excellent adhesive properties and environmental resistance. - What applications benefit from battery potting?

Applications include consumer electronics, electric vehicles, renewable energy systems, where durability and reliability are critical.

Potting Application for Battery Pack Production

As the automotive industry races to achieve net-zero emissions targets through a massive shift to electrification, ensuring battery safety remains one of the most critical prerequisites for mass adoption of electric vehicles, and therefore a top priority for OEMs and battery manufacturers. With reports of various electric vehicles catching fire under different circumstances, manufacturers, consumers and regulators are focusing on the topic of fire protection and battery safety, and are increasingly concerned about the safety of passengers and the road.