- Lithium Golf Cart Battery

- Forklift Lithium Battery

-

48V

- 48V 210Ah

- 48V 300Ah

- 48V 420Ah (949 x 349 x 569 mm)

- 48V 420Ah (950 x 421 x 450 mm)

- 48V 456Ah

- 48V 460Ah (830 x 630 x 590 mm)

- 48V 460Ah (950 x 421 x 450 mm)

- 48V 460Ah (800 x 630 x 600 mm)

- 48V 460Ah (820 x 660 x 470 mm)

- 48V 500Ah

- 48V 560Ah (810 x 630 x 600 mm)

- 48V 560Ah (950 x 592 x 450 mm)

- 48V 600Ah

- 48V 630Ah

-

48V

- 12V Lithium Battery

12V 150Ah Lithium RV Battery

Bluetooth App | BCI Group 31

LiFePO4 Lithium

Discharge Temperature -20°C ~ 65°C

Fast Charger 14.6V 50A

Solar MPPT Charging - 24V Lithium Battery

- 36V Lithium Battery

- 48V Lithium Battery

-

48V LiFePO4 Battery

- 48V 50Ah

- 48V 50Ah (for Golf Carts)

- 48V 60Ah (8D)

- 48V 100Ah (8D)

- 48V 100Ah

- 48V 100Ah (Discharge 100A for Golf Carts)

- 48V 100Ah (Discharge 150A for Golf Carts)

- 48V 100Ah (Discharge 200A for Golf Carts)

- 48V 150Ah (for Golf Carts)

- 48V 160Ah (Discharge 100A for Golf Carts)

- 48V 160Ah (Discharge 160A for Golf Carts)

-

48V LiFePO4 Battery

- 60V Lithium Battery

-

60V LiFePO4 Battery

- 60V 20Ah

- 60V 30Ah

- 60V 50Ah

- 60V 50Ah (Small Size / Side Terminal)

- 60V 100Ah (for Electric Motocycle, Electric Scooter, LSV, AGV)

- 60V 100Ah (for Forklift, AGV, Electric Scooter, Sweeper)

- 60V 150Ah (E-Motocycle / E-Scooter / E-Tricycle / Tour LSV)

- 60V 200Ah (for Forklift, AGV, Electric Scooter, Sweeper)

-

60V LiFePO4 Battery

- 72V~96V Lithium Battery

- Rack-mounted Lithium Battery

- E-Bike Battery

- All-in-One Home-ESS

- Wall-mount Battery ESS

-

Home-ESS Lithium Battery PowerWall

- 24V 100Ah 2.4kWh PW24100-S PowerWall

- 48V 50Ah 2.4kWh PW4850-S PowerWall

- 48V 50Ah 2.56kWh PW5150-S PowerWall

- 48V 100Ah 5.12kWh PW51100-F PowerWall (IP65)

- 48V 100Ah 5.12kWh PW51100-S PowerWall

- 48V 100Ah 5.12kWh PW51100-H PowerWall

- 48V 200Ah 10kWh PW51200-H PowerWall

- 48V 300Ah 15kWh PW51300-H PowerWall

PowerWall 51.2V 100Ah LiFePO4 Lithium Battery

Highly popular in Asia and Eastern Europe.

CE Certification | Home-ESS -

Home-ESS Lithium Battery PowerWall

- Portable Power Stations

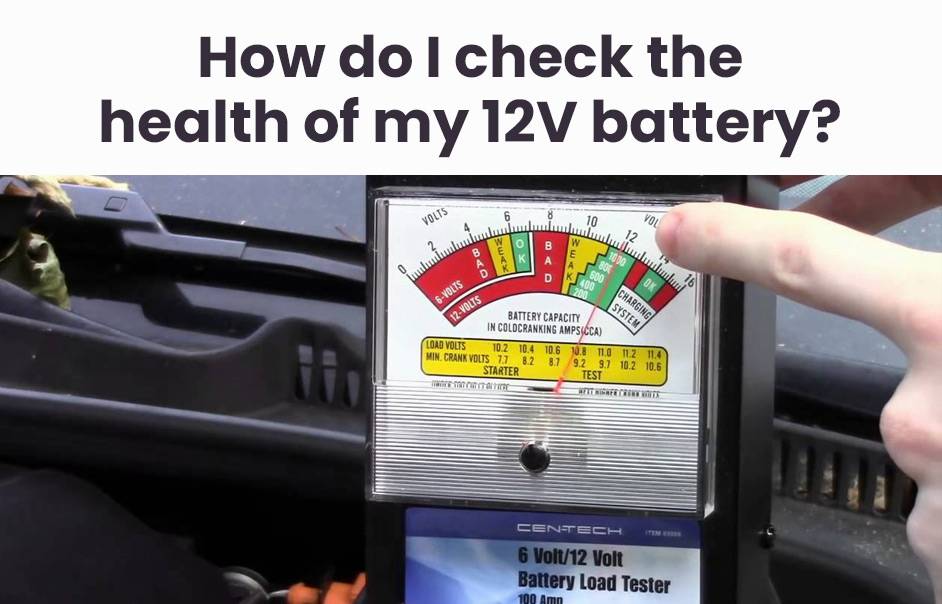

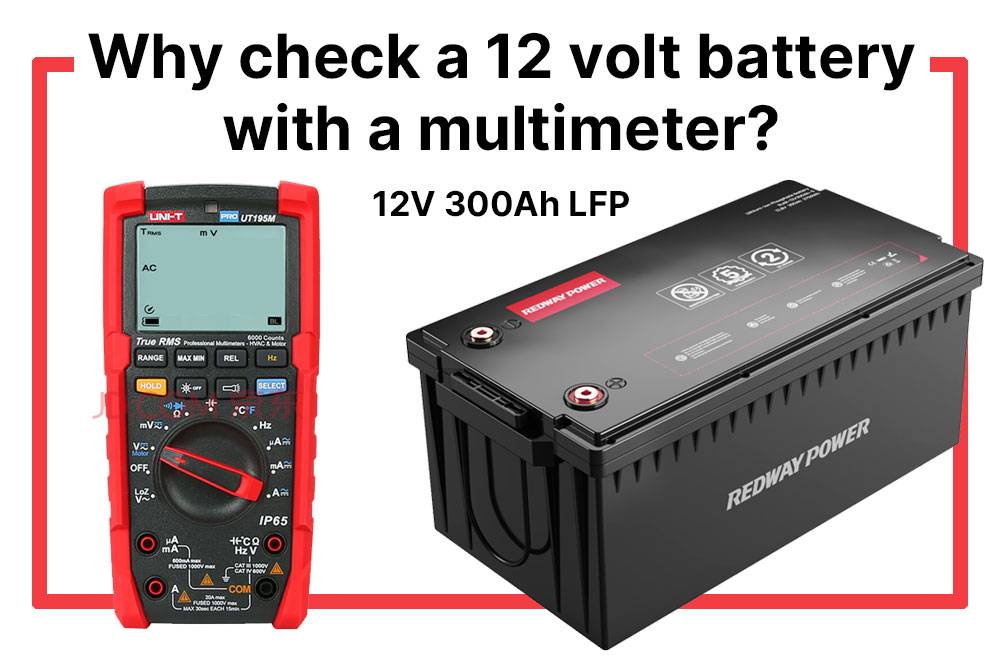

How to Properly Test a 12V Battery Using a Multimeter

Testing a 12V battery using a multimeter is essential for diagnosing battery health and performance. To perform this test, you will need basic materials including a multimeter and safety gear. Proper testing ensures that your battery operates efficiently and helps prevent unexpected failures.

What Materials Are Needed to Test a 12V Battery?

To test a 12V battery effectively, gather the following materials:

- Digital Multimeter: This device measures voltage, current, and resistance.

- Safety Gear: Safety goggles and gloves are recommended to protect against accidental spills or shorts.

- Clean Cloth: For cleaning battery terminals if necessary.

Having these materials ready ensures that you can conduct your tests safely and accurately.Chart: Essential Materials for Testing

| Material | Purpose |

|---|---|

| Digital Multimeter | Measures voltage and current |

| Safety Goggles | Protects eyes from potential hazards |

| Gloves | Prevents skin contact with battery acid |

| Clean Cloth | Cleans terminals for accurate connections |

How Do You Set Up Your Multimeter for Testing a 12V Battery?

Setting up your multimeter is straightforward:

- Turn on the Multimeter: Ensure it is functioning properly.

- Select DC Voltage: Rotate the dial to select the DC voltage setting, typically marked as “V” with a solid line and dashed line beneath it.

- Choose the Correct Range: Set it to measure at least 20 volts, which is suitable for testing 12V batteries.

This setup allows your multimeter to accurately read the voltage levels of your battery.Chart: Multimeter Settings

| Setting | Description |

|---|---|

| DC Voltage | Measures direct current voltage |

| Range Selection | Choose at least 20 volts for 12V batteries |

How Do You Connect the Probes to the Battery for Accurate Readings?

To connect the probes correctly:

- Identify Terminals: Locate the positive (+) and negative (-) terminals on your battery.

- Connect Probes:

- Attach the red probe to the positive terminal.

- Attach the black probe to the negative terminal.

- Ensure Good Contact: Make sure that both probes maintain consistent contact with their respective terminals during measurement.

Proper connection is crucial for obtaining accurate voltage readings.

What Are the Expected Voltage Readings for a Healthy 12V Battery?

A healthy 12V battery should ideally read between 12.6 volts and 12.8 volts when fully charged at rest. Here’s how different readings indicate battery health:

- Above 12.6V: Fully charged.

- 12.4V – 12.6V: Moderately charged, may need charging soon.

- Below 12.4V: Considered discharged; recharging is necessary.

Understanding these readings helps you assess whether your battery needs maintenance or replacement.Chart: Voltage Readings Interpretation

| Voltage Reading | Condition |

|---|---|

| Above 12.6V | Fully charged |

| 12.4V – 12.6V | Moderately charged |

| Below 12.4V | Discharged |

What Should You Do If Your 12V Battery Shows Low Voltage?

If your battery shows low voltage readings:

- Recharge Immediately: Use an appropriate charger designed for your battery type.

- Check Connections: Ensure that all connections are clean and secure; corrosion can lead to inaccurate readings.

- Test Again After Charging: After recharging, retest using your multimeter to confirm if it holds charge.

If low voltage persists after charging, consider replacing the battery as it may be failing.

Industrial News

Recent developments in battery technology emphasize advancements in lithium-ion batteries, which offer improved efficiency and longer lifespans compared to traditional lead-acid batteries. These innovations are particularly relevant in automotive applications where reliable power sources are critical. Additionally, manufacturers are focusing on developing smarter charging systems that enhance battery health monitoring capabilities.

Redway Power Insights

“Understanding how to properly test your battery can save you time and money,” states an expert at Redway Power. “Regular checks not only help maintain performance but also extend the lifespan of your batteries.” As technology evolves, staying informed about proper testing methods is essential for any vehicle owner or enthusiast.

How to test a 12V battery with a multimeter?

How to test 12V Battery with Multimeter

FAQs

How do you rejuvenate a golf cart battery?

How do you check the life of a golf cart battery?

How do you test golf cart batteries to see if they’re good?

How do I know if my golf cart battery is bad?

Are there lithium batteries with a built-in BMS?