- Lithium Golf Cart Battery

- Forklift Lithium Battery

-

48V

- 48V 210Ah

- 48V 300Ah

- 48V 420Ah (949 x 349 x 569 mm)

- 48V 420Ah (950 x 421 x 450 mm)

- 48V 456Ah

- 48V 460Ah (830 x 630 x 590 mm)

- 48V 460Ah (950 x 421 x 450 mm)

- 48V 460Ah (800 x 630 x 600 mm)

- 48V 460Ah (820 x 660 x 470 mm)

- 48V 500Ah

- 48V 560Ah (810 x 630 x 600 mm)

- 48V 560Ah (950 x 592 x 450 mm)

- 48V 600Ah

- 48V 630Ah

-

48V

- 12V Lithium Battery

12V 150Ah Lithium RV Battery

Bluetooth App | BCI Group 31

LiFePO4 Lithium

Discharge Temperature -20°C ~ 65°C

Fast Charger 14.6V 50A

Solar MPPT Charging - 24V Lithium Battery

- 36V Lithium Battery

- 48V Lithium Battery

-

48V LiFePO4 Battery

- 48V 50Ah

- 48V 50Ah (for Golf Carts)

- 48V 60Ah (8D)

- 48V 100Ah (8D)

- 48V 100Ah

- 48V 100Ah (Discharge 100A for Golf Carts)

- 48V 100Ah (Discharge 150A for Golf Carts)

- 48V 100Ah (Discharge 200A for Golf Carts)

- 48V 150Ah (for Golf Carts)

- 48V 160Ah (Discharge 100A for Golf Carts)

- 48V 160Ah (Discharge 160A for Golf Carts)

-

48V LiFePO4 Battery

- 60V Lithium Battery

-

60V LiFePO4 Battery

- 60V 20Ah

- 60V 30Ah

- 60V 50Ah

- 60V 50Ah (Small Size / Side Terminal)

- 60V 100Ah (for Electric Motocycle, Electric Scooter, LSV, AGV)

- 60V 100Ah (for Forklift, AGV, Electric Scooter, Sweeper)

- 60V 150Ah (E-Motocycle / E-Scooter / E-Tricycle / Tour LSV)

- 60V 200Ah (for Forklift, AGV, Electric Scooter, Sweeper)

-

60V LiFePO4 Battery

- 72V~96V Lithium Battery

- Rack-mounted Lithium Battery

- E-Bike Battery

- All-in-One Home-ESS

- Wall-mount Battery ESS

-

Home-ESS Lithium Battery PowerWall

- 24V 100Ah 2.4kWh PW24100-S PowerWall

- 48V 50Ah 2.4kWh PW4850-S PowerWall

- 48V 50Ah 2.56kWh PW5150-S PowerWall

- 48V 100Ah 5.12kWh PW51100-F PowerWall (IP65)

- 48V 100Ah 5.12kWh PW51100-S PowerWall

- 48V 100Ah 5.12kWh PW51100-H PowerWall

- 48V 200Ah 10kWh PW51200-H PowerWall

- 48V 300Ah 15kWh PW51300-H PowerWall

PowerWall 51.2V 100Ah LiFePO4 Lithium Battery

Highly popular in Asia and Eastern Europe.

CE Certification | Home-ESS -

Home-ESS Lithium Battery PowerWall

- Portable Power Stations

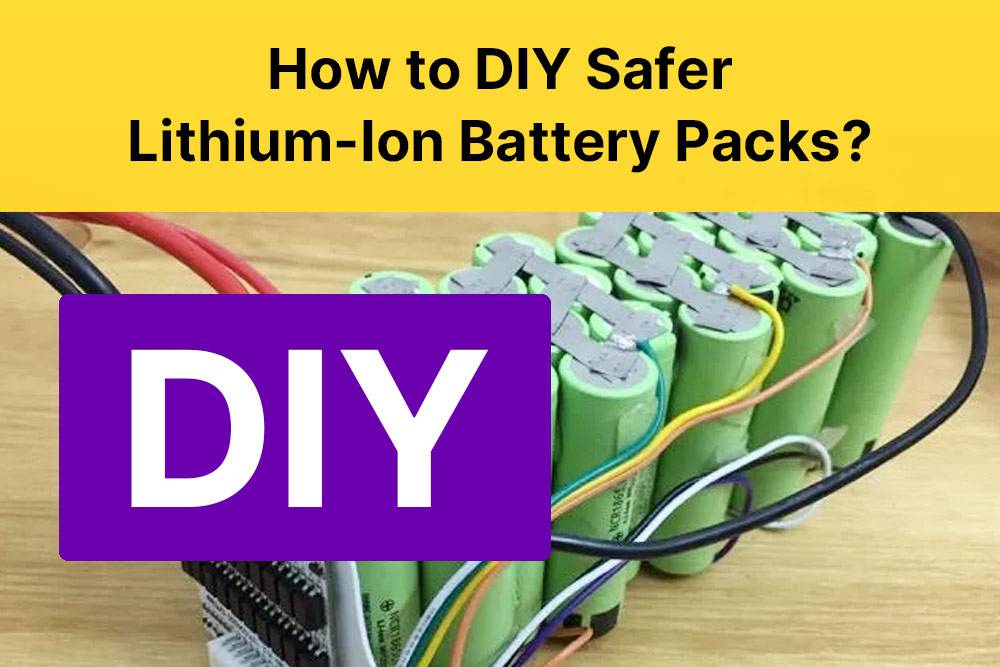

How to DIY Safer Lithium-Ion Battery Packs

Do You Need BMS for DIY Lithium-Ion Battery Packs?

Ready to dive into the exciting world of building your own safe lithium-ion battery pack? Let’s get started with a step-by-step guide that will help you create a reliable power source for your projects.

First, gather all the necessary tools and equipment. You’ll need lithium-ion battery cells, nickel strips, spot welder, insulating materials like fish paper or kapton tape, and a battery management system (BMS).

Next, carefully plan the layout of your battery pack to ensure even distribution of cells in parallel. This helps balance the load across the entire pack and prevents overcharging or overheating.

Now comes the assembly process. Use caution when spot welding the nickel strips to connect the cells together. Ensure each connection is strong and secure to avoid any potential short circuits.

After assembling your battery pack, don’t forget to test it using a multimeter and BMS to check for proper voltage levels and cell balancing.

Once everything checks out, properly encase your DIY battery pack in a protective housing to prevent any damage or accidental exposure. Now you’re ready to power up your projects safely!

FAQs

Disadvantages of LiFePO4 Batteries?

LiFePO4 batteries have some disadvantages to consider, including limited energy density, larger physical size and weight, and higher upfront cost. However, they are known for their excellent safety performance, long cycle life, and stable thermal characteristics, making them a reliable choice for various applications.

Can Car Alternator Charge LiFePO4 Battery?

While it is technically possible to charge a LiFePO4 battery using a car alternator, it is not recommended without a suitable charging system. Car alternators are designed for lead-acid batteries and may not provide the specific charging algorithms required for LiFePO4 batteries. To ensure optimal performance and longevity, it is advisable to use a dedicated LiFePO4 battery charger or a charging system designed for lithium-ion batteries.

Use LiFePO4 Battery in Car?

LiFePO4 batteries can be used as an alternative to lead-acid batteries in cars, offering advantages such as higher energy density and longer cycle life. However, compatibility with the car’s electrical system and appropriate charging systems are essential. Additionally, modifications may be required to accommodate the different physical dimensions and weight of LiFePO4 batteries. Consult with experts and follow recommended guidelines for a successful integration of LiFePO4 batteries in car applications.

Advantages of LiFePO4 in Electric Vehicles

LiFePO4 batteries offer distinct advantages when used in electric vehicles. They provide enhanced safety features, including a lower risk of thermal runaway and resistance to overcharging and short circuits. With a longer cycle life and higher tolerance for extreme temperatures, LiFePO4 batteries are a reliable choice for electric vehicles, ensuring prolonged battery performance and durability.

Compatibility of LiFePO4 for Electric Vehicles Use

LiFePO4 batteries are compatible with electric vehicle (EV) use, provided that the battery management system (BMS) is designed for LiFePO4 chemistry. The BMS must monitor and control the charging and discharging processes specific to LiFePO4 batteries. Additionally, the electrical system of the EV must be compatible with the voltage and power requirements of LiFePO4 batteries. Consult with experts to ensure proper integration and compatibility for optimal performance and safety in electric vehicles.

What materials do I need to build a lithium-ion battery pack?

You will need lithium-ion cells, a battery management system (BMS), nickel strips, soldering tools, and insulation materials.How do I safely assemble a lithium-ion battery pack?

Arrange cells in your desired configuration, connect them with nickel strips using proper soldering techniques, and insulate connections to prevent short circuits.Why is a BMS important for my battery pack?

A BMS monitors cell voltages, balances charge levels, and protects against overcharging or short circuits, enhancing overall safety.What safety precautions should I take while building battery packs?

Wear safety goggles and gloves, work in a well-ventilated area, avoid flammable materials, and keep a fire extinguisher nearby.How can I test my DIY battery pack after assembly?

Use a multimeter to check voltage levels and perform load tests to ensure it meets performance requirements while monitoring temperature during initial use.By following these guidelines for building lithium-ion battery packs safely, you can create efficient energy storage solutions tailored to your specific needs while minimizing risks associated with DIY projects.