- Lithium Golf Cart Battery

- Forklift Lithium Battery

-

48V

- 48V 210Ah

- 48V 300Ah

- 48V 420Ah (949 x 349 x 569 mm)

- 48V 420Ah (950 x 421 x 450 mm)

- 48V 456Ah

- 48V 460Ah (830 x 630 x 590 mm)

- 48V 460Ah (950 x 421 x 450 mm)

- 48V 460Ah (800 x 630 x 600 mm)

- 48V 460Ah (820 x 660 x 470 mm)

- 48V 500Ah

- 48V 560Ah (810 x 630 x 600 mm)

- 48V 560Ah (950 x 592 x 450 mm)

- 48V 600Ah

- 48V 630Ah

-

48V

- 12V Lithium Battery

12V 150Ah Lithium RV Battery

Bluetooth App | BCI Group 31

LiFePO4 Lithium

Discharge Temperature -20°C ~ 65°C

Fast Charger 14.6V 50A

Solar MPPT Charging - 24V Lithium Battery

- 36V Lithium Battery

- 48V Lithium Battery

-

48V LiFePO4 Battery

- 48V 50Ah

- 48V 50Ah (for Golf Carts)

- 48V 60Ah (8D)

- 48V 100Ah (8D)

- 48V 100Ah

- 48V 100Ah (Discharge 100A for Golf Carts)

- 48V 100Ah (Discharge 150A for Golf Carts)

- 48V 100Ah (Discharge 200A for Golf Carts)

- 48V 150Ah (for Golf Carts)

- 48V 160Ah (Discharge 100A for Golf Carts)

- 48V 160Ah (Discharge 160A for Golf Carts)

-

48V LiFePO4 Battery

- 60V Lithium Battery

-

60V LiFePO4 Battery

- 60V 20Ah

- 60V 30Ah

- 60V 50Ah

- 60V 50Ah (Small Size / Side Terminal)

- 60V 100Ah (for Electric Motocycle, Electric Scooter, LSV, AGV)

- 60V 100Ah (for Forklift, AGV, Electric Scooter, Sweeper)

- 60V 150Ah (E-Motocycle / E-Scooter / E-Tricycle / Tour LSV)

- 60V 200Ah (for Forklift, AGV, Electric Scooter, Sweeper)

-

60V LiFePO4 Battery

- 72V~96V Lithium Battery

- Rack-mounted Lithium Battery

- E-Bike Battery

- All-in-One Home-ESS

- Wall-mount Battery ESS

-

Home-ESS Lithium Battery PowerWall

- 24V 100Ah 2.4kWh PW24100-S PowerWall

- 48V 50Ah 2.4kWh PW4850-S PowerWall

- 48V 50Ah 2.56kWh PW5150-S PowerWall

- 48V 100Ah 5.12kWh PW51100-F PowerWall (IP65)

- 48V 100Ah 5.12kWh PW51100-S PowerWall

- 48V 100Ah 5.12kWh PW51100-H PowerWall

- 48V 200Ah 10kWh PW51200-H PowerWall

- 48V 300Ah 15kWh PW51300-H PowerWall

PowerWall 51.2V 100Ah LiFePO4 Lithium Battery

Highly popular in Asia and Eastern Europe.

CE Certification | Home-ESS -

Home-ESS Lithium Battery PowerWall

- Portable Power Stations

How often should emergency light batteries be replaced?

When it comes to ensuring safety in any building, emergency lighting plays a critical role. Whether it’s a residential home, office space, or commercial establishment, having reliable emergency lights is essential for guiding people to safety during power outages or emergencies. But have you ever wondered about the batteries that power these life-saving lights? How often should they be replaced? In this blog post, we’ll explore the importance of emergency light batteries and provide some valuable insights on when and how frequently they should be replaced. So let’s shed some light on this crucial topic!

The Purpose of Emergency Light Batteries

Emergency light batteries are crucial for ensuring safety during power outages or emergencies. Serving as a reliable backup, they keep emergency lights functioning, allowing people to navigate their surroundings safely.

- Critical Functionality:

- Key Point: Essential Illumination: Emergency light batteries are vital in providing sufficient illumination for evacuation routes, stairwells, and critical areas during situations like natural disasters or building evacuations.

- Failsafe Mechanism:

- Key Point: Automatic Activation: These batteries act as failsafe mechanisms, automatically kicking in when the main power supply fails. This ensures continuous functionality of emergency lighting systems until power is restored.

- Types of Batteries:

- Key Points:

- Diverse Options: Different battery types such as lead-acid, nickel-cadmium (Ni-Cd), and lithium-ion (Li-ion) offer unique characteristics and performance capabilities.

- Varied Choices: Choosing the right battery type is crucial for optimal emergency lighting system performance.

- Key Points:

- Maintenance Guidelines:

- Key Points:

- Regular Inspections: Routine checks on battery voltage levels, connection integrity, cleanliness, and overall condition are essential.

- Optimal Performance: Following recommended guidelines for inspection and maintenance ensures the emergency lighting system remains reliable when needed most.

- Key Points:

Factors that Affect Battery Life

- Battery Type:

- Key Point: Diverse Lifespans: Different battery types, such as lead-acid or nickel-cadmium, have varying lifespans. Lead-acid lasts around 3-5 years, while nickel-cadmium can reach up to 10 years with proper maintenance.

- Testing and Usage Frequency:

- Key Point: Usage Impact: Batteries frequently discharged and recharged have a shorter lifespan compared to less-used ones.

- Environmental Conditions:

- Key Point: Temperature Impact: Extreme temperatures (hot or cold) reduce battery performance and longevity. Keeping emergency lights within recommended temperature ranges is crucial.

- Maintenance Practices:

- Key Points:

- Regular Inspection: Checking terminals, cleaning, and replacing faulty components are crucial for extending battery life.

- Corrosion Prevention: Taking steps to prevent corrosion contributes significantly to battery longevity.

- Key Points:

- Power Quality Issues:

- Key Point: Voltage Management: Voltage spikes or surges can impact battery lifespan. Installing surge protectors or voltage regulators helps mitigate these issues and extends battery life.

Optimizing Battery Life: By considering battery type, managing testing frequency, maintaining environmental conditions, practicing regular maintenance, and addressing power quality issues, it’s possible to optimize emergency light system performance while maximizing battery lifespan.

Recommended Replacement Schedule for Different Types of Batteries

- Lead-Acid Batteries:

- Replacement Interval: Every 2-3 Years

- Key Point: Limited Lifespan: Due to their chemical composition, lead-acid batteries tend to lose capacity over time. Regular voltage checks and load tests help determine replacement needs.

- Lithium-Ion Batteries:

- Replacement Interval: Every 5-7 Years

- Key Point: Extended Lifespan: Advanced lithium-ion batteries offer longer lifespans and require less frequent replacements compared to traditional lead-acid batteries.

Warning Signs for Immediate Replacement:

- Key Signs:

- Dim or Flickering Lights

- Long Recharge Times

- Inconsistent Discharge Rates

Maintenance Practices for Optimal Performance:

- Key Practices:

- Clean Terminals: Keep battery terminals free from corrosion.

- Regular Testing: Simulate power outages to test the backup lighting system.

- Follow Guidelines: Adhere to manufacturer guidelines for charging cycles.

Adhering to a recommended replacement schedule based on battery type, coupled with diligent maintenance practices, ensures optimal functionality of emergency lights during critical situations. Act on warning signs and follow a proactive approach to keep your emergency lights always ready when needed most.

Signs that Indicate a Need for Battery Replacement

- Failure to Illuminate:

- Key Sign: No Light or Short Illumination

- Indication: Diminished battery capacity, requiring replacement for continued functionality.

- Dimming or Flickering:

- Key Sign: Dimming or Flickering Lights

- Indication: Potential battery issues, necessitating a check and possible replacement.

- Unusual Noises or Odors:

- Key Signs: Hissing Sounds, Strong Odor

- Indication: Battery leak, requiring immediate replacement for safety and functionality.

- Extended Usage Without Replacement:

- Key Point: Proactive Replacement

- Indication: After several years of use without a battery change, proactive replacement is advised due to the limited lifespan of batteries.

- Regular Maintenance and Inspections:

- Key Practice: Monitor and Record

- Indication: Regularly scheduled inspections and maintenance help identify potential issues early, ensuring timely battery replacements.

By paying attention to signs like failure to illuminate, dimming or flickering, unusual noises, and being proactive with replacements based on usage duration, you can maintain the reliability of emergency lights. Regular maintenance and vigilance contribute to the safety and functionality of these critical systems during emergencies.

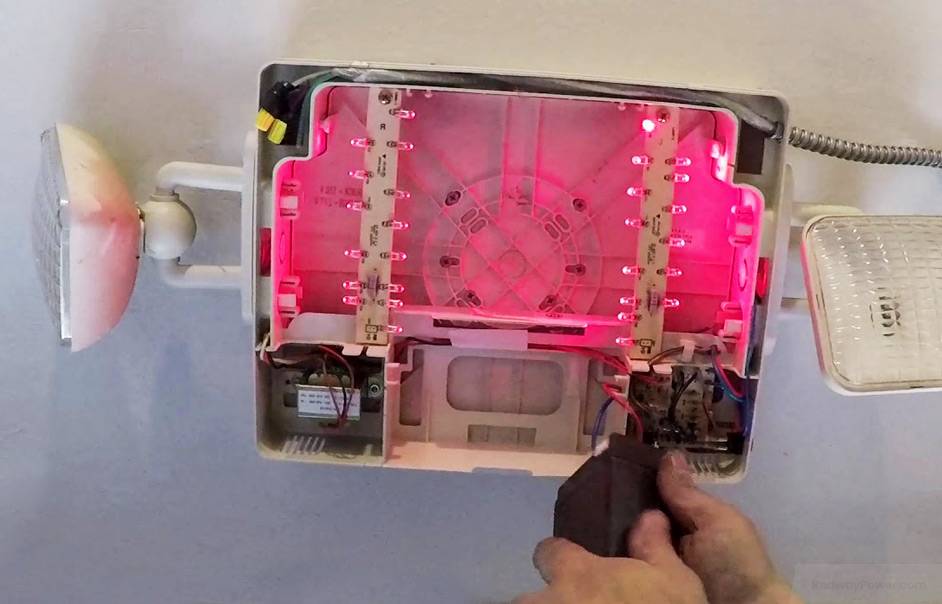

Tips for Proper Maintenance of Emergency Light Batteries

- Regular Testing:

- Key Tip: Monthly Discharge Tests

- Importance: Ensure correct functionality by pressing the “test” button or conducting regular discharge tests.

- Cleanliness:

- Key Tip: Keep Terminals Clean

- Importance: Remove dirt and debris using a soft cloth or brush to prevent corrosion and maintain battery performance.

- Temperature Control:

- Key Tip: Store in Cool, Dry Place

- Importance: Protect battery life by avoiding extreme temperatures and storing emergency lights away from direct sunlight or heat sources.

- Charging Routine:

- Key Tip: Follow Manufacturer’s Instructions

- Importance: Proper charging according to guidelines prevents overcharging or undercharging, preserving battery capacity over time.

- Battery Replacement:

- Key Tip: Scheduled Replacements

- Recommendation: Replace sealed lead acid (SLA) batteries every 3-5 years and nickel-cadmium (Ni-Cd) batteries every 2-4 years, even with proper maintenance.

By incorporating regular testing, maintaining cleanliness, controlling temperatures, adhering to charging routines, and scheduling timely replacements, you can maximize the efficiency of your emergency lighting system. These simple maintenance tips ensure your system is ready and reliable when needed most.

Ensuring Reliable Emergency Lighting with Regular Battery Replacements

Maintaining reliable emergency lighting requires consistent battery replacements. Prioritize the following practices to ensure optimal functionality when it matters most:

- Follow Replacement Schedules:

- Key Point: Adherence to Recommendations

- Importance: Ensure timely replacements based on manufacturer-recommended schedules for different battery types.

- Vigilance for Signs:

- Key Point: Immediate Action on Indications

- Importance: Be attentive to signs like dimming lights, flickering, or extended recharge times, signaling the need for immediate battery replacement.

- Understanding Factors:

- Key Point: Consider Battery Type, Usage, and Environment

- Importance: Recognize factors affecting battery life, such as type, usage patterns, and environmental conditions, to implement effective care practices.

- Regular Maintenance Tasks:

- Key Practices:

- Inspections: Regularly check for damage or corrosion.

- Testing: Ensure emergency lights meet brightness requirements.

- Cleaning: Keep the surroundings free from dust or debris that might impact performance.

- Key Practices:

Prioritizing regular battery replacements, guided by recommended schedules and vigilance for signs, is essential for a reliable emergency lighting system. Consistent adherence to care practices ensures optimal functionality when needed most, contributing to the safety of building occupants during unforeseen events. Stay proactive in maintaining your emergency lighting—every second counts.