- Forklift Lithium Battery

-

48V

- 48V 210Ah

- 48V 300Ah

- 48V 420Ah (949 x 349 x 569 mm)

- 48V 420Ah (950 x 421 x 450 mm)

- 48V 456Ah

- 48V 460Ah (830 x 630 x 590 mm)

- 48V 460Ah (950 x 421 x 450 mm)

- 48V 460Ah (800 x 630 x 600 mm)

- 48V 460Ah (820 x 660 x 470 mm)

- 48V 500Ah

- 48V 560Ah (810 x 630 x 600 mm)

- 48V 560Ah (950 x 592 x 450 mm)

- 48V 600Ah

- 48V 630Ah

-

48V

- Lithium Golf Cart Battery

- 12V Lithium Battery

12V 150Ah Lithium RV Battery

Bluetooth App | BCI Group 31

LiFePO4 Lithium

Discharge Temperature -20°C ~ 65°C

Fast Charger 14.6V 50A

Solar MPPT Charging - 24V Lithium Battery

- 36V Lithium Battery

- 48V Lithium Battery

-

48V LiFePO4 Battery

- 48V 50Ah

- 48V 50Ah (for Golf Carts)

- 48V 60Ah (8D)

- 48V 100Ah (8D)

- 48V 100Ah

- 48V 100Ah (Discharge 100A for Golf Carts)

- 48V 100Ah (Discharge 150A for Golf Carts)

- 48V 100Ah (Discharge 200A for Golf Carts)

- 48V 150Ah (for Golf Carts)

- 48V 160Ah (Discharge 100A for Golf Carts)

- 48V 160Ah (Discharge 160A for Golf Carts)

-

48V LiFePO4 Battery

- 60V Lithium Battery

-

60V LiFePO4 Battery

- 60V 20Ah

- 60V 30Ah

- 60V 50Ah

- 60V 50Ah (Small Size / Side Terminal)

- 60V 100Ah (for Electric Motocycle, Electric Scooter, LSV, AGV)

- 60V 100Ah (for Forklift, AGV, Electric Scooter, Sweeper)

- 60V 150Ah (E-Motocycle / E-Scooter / E-Tricycle / Tour LSV)

- 60V 200Ah (for Forklift, AGV, Electric Scooter, Sweeper)

-

60V LiFePO4 Battery

- 72V~96V Lithium Battery

- Rack-mounted Lithium Battery

- E-Bike Battery

- All-in-One Home-ESS

- Wall-mount Battery ESS

-

Home-ESS Lithium Battery PowerWall

- 24V 100Ah 2.4kWh PW24100-S PowerWall

- 48V 50Ah 2.4kWh PW4850-S PowerWall

- 48V 50Ah 2.56kWh PW5150-S PowerWall

- 48V 100Ah 5.12kWh PW51100-F PowerWall (IP65)

- 48V 100Ah 5.12kWh PW51100-S PowerWall

- 48V 100Ah 5.12kWh PW51100-H PowerWall

- 48V 200Ah 10kWh PW51200-H PowerWall

- 48V 300Ah 15kWh PW51300-H PowerWall

PowerWall 51.2V 100Ah LiFePO4 Lithium Battery

Highly popular in Asia and Eastern Europe.

CE Certification | Home-ESS -

Home-ESS Lithium Battery PowerWall

- Portable Power Stations

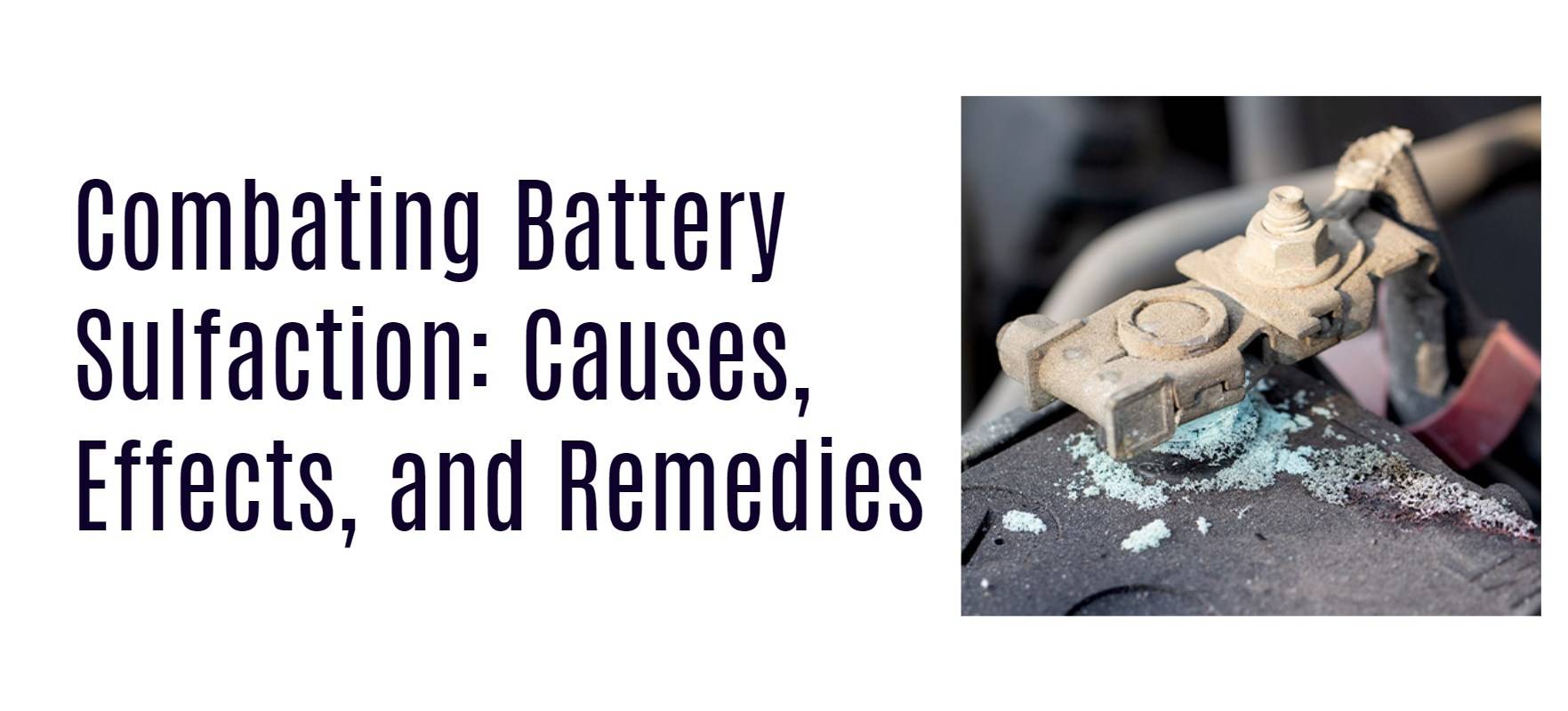

How to Combat Battery Sulfaction: Causes, Effects, and Remedies

Battery sulfaction, a common issue in lead-acid batteries, occurs when lead sulfate crystals build up on the battery plates, leading to reduced efficiency and capacity. Understanding the causes, effects, and remedies for sulfaction is crucial for maintaining battery health and longevity. This article provides comprehensive insights into combating battery sulfaction effectively.

What is battery sulfaction and how does it occur?

Battery sulfaction refers to the accumulation of lead sulfate crystals on the plates of lead-acid batteries. It typically occurs during the discharge cycle when the sulfuric acid in the electrolyte reacts with the lead plates. If the battery is not fully charged regularly, these sulfate crystals can harden, leading to irreversible damage.Sulfaction can be triggered by several factors:

- Undercharging: Failing to charge the battery fully allows sulfate crystals to form.

- Overcharging: Excessive charging can also lead to sulfate build-up.

- Long Storage: Leaving a battery discharged for extended periods promotes sulfaction.

Chart: Causes of Battery Sulfaction

| Cause | Description |

|---|---|

| Undercharging | Insufficient charge leads to crystal formation |

| Overcharging | Excessive voltage causes overheating |

| Long Storage | Discharged batteries left idle promote buildup |

What are the effects of sulfaction on battery performance?

Sulfaction has several detrimental effects on battery performance:

- Reduced Capacity: The presence of lead sulfate crystals decreases the effective surface area available for chemical reactions, leading to lower capacity.

- Longer Charging Times: Sulfation increases internal resistance, making it harder for the battery to accept charge.

- Shortened Lifespan: Continuous exposure to sulfation can significantly reduce the overall lifespan of the battery.

- Difficulty Starting Equipment: In applications like vehicles or power tools, a sulfated battery may struggle to provide sufficient power for starting.

Chart: Effects of Battery Sulfaction

| Effect | Description |

|---|---|

| Reduced Capacity | Lower available energy storage |

| Longer Charging Times | Increased resistance slows down charging |

| Shortened Lifespan | Permanent damage from prolonged exposure |

| Difficulty Starting | Insufficient power for operational demands |

How can you identify a sulfated battery?

Identifying a sulfated battery involves looking for specific signs:

- Voltage Drops: A significant drop in voltage under load indicates potential sulfation.

- Long Charging Times: If your battery takes longer than usual to charge, it may be suffering from sulfation.

- Physical Inspection: Look for signs of corrosion or bulging cases, which may indicate internal damage due to sulfation.

Chart: Signs of a Sulfated Battery

| Sign | Description |

|---|---|

| Voltage Drops | Noticeable decrease under load |

| Long Charging Times | Extended periods required for full charge |

| Physical Damage | Corrosion or bulging cases |

What methods can reverse or remedy sulfaction in batteries?

Several methods can help reverse or mitigate the effects of sulfaction:

- Equalization Charging: This involves applying a controlled overcharge to break down lead sulfate crystals. It should be done carefully according to manufacturer guidelines.

- Desulfating Chargers: Specialized chargers that apply pulses or high-frequency currents can help dissolve sulfate crystals.

- Regular Maintenance Charging: Keeping batteries at full charge with maintenance chargers prevents buildup from occurring.

Chart: Methods to Remedy Battery Sulfaction

| Method | Description |

|---|---|

| Equalization Charging | Controlled overcharging helps dissolve crystals |

| Desulfating Chargers | Pulses or high-frequency currents aid recovery |

| Maintenance Charging | Regularly keeping batteries charged prevents buildup |

What preventive measures can be taken to avoid battery sulfaction?

To prevent battery sulfaction, consider these best practices:

- Regular Charging: Ensure that batteries are charged fully after each use and avoid deep discharges.

- Proper Storage Conditions: Store batteries in a cool, dry place and maintain them at full charge if not in use.

- Temperature Management: Avoid exposing batteries to extreme temperatures, which can accelerate self-discharge and promote sulfation.

Chart: Preventive Measures Against Sulfaction

| Measure | Recommendation |

|---|---|

| Regular Charging | Charge fully after each use |

| Proper Storage | Keep in cool, dry environments |

| Temperature Management | Avoid extreme heat or cold |

Industrial News

Recent advancements in lead-acid battery technology focus on improving maintenance practices and developing smart charging solutions that help prevent sulfation. Manufacturers are introducing innovative desulfating chargers that utilize pulse technology, allowing users to maintain their batteries more effectively and extend their lifespan significantly.

Redway Power Insight

“Understanding how to combat battery sulfaction through proper maintenance and charging practices is essential for maximizing performance,” states an industry expert. “By taking proactive steps, users can ensure their batteries remain reliable and efficient over time.”

FAQ Section

Q1: Can I still use a sulfated battery?

A1: While you can attempt to revive it using specific methods, its performance may be compromised.Q2: How often should I check my lead-acid batteries?

A2: Regular checks every month are advisable, especially before heavy usage periods.Q3: Is there any way to prevent sulfation?

A3: Yes, regular charging and avoiding deep discharges are effective prevention strategies.Q4: What temperature is best for storing batteries?

A4: Store your batteries at temperatures between 15°C (59°F) and 25°C (77°F).Q5: How do I know if my charger is suitable for my battery?

A5: Always refer to your manufacturer’s specifications regarding charger compatibility with your specific type of battery.