- Lithium Golf Cart Battery

- Forklift Lithium Battery

-

48V

- 48V 210Ah

- 48V 300Ah

- 48V 420Ah (949 x 349 x 569 mm)

- 48V 420Ah (950 x 421 x 450 mm)

- 48V 456Ah

- 48V 460Ah (830 x 630 x 590 mm)

- 48V 460Ah (950 x 421 x 450 mm)

- 48V 460Ah (800 x 630 x 600 mm)

- 48V 460Ah (820 x 660 x 470 mm)

- 48V 500Ah

- 48V 560Ah (810 x 630 x 600 mm)

- 48V 560Ah (950 x 592 x 450 mm)

- 48V 600Ah

- 48V 630Ah

-

48V

- 12V Lithium Battery

12V 150Ah Lithium RV Battery

Bluetooth App | BCI Group 31

LiFePO4 Lithium

Discharge Temperature -20°C ~ 65°C

Fast Charger 14.6V 50A

Solar MPPT Charging - 24V Lithium Battery

- 36V Lithium Battery

- 48V Lithium Battery

-

48V LiFePO4 Battery

- 48V 50Ah

- 48V 50Ah (for Golf Carts)

- 48V 60Ah (8D)

- 48V 100Ah (8D)

- 48V 100Ah

- 48V 100Ah (Discharge 100A for Golf Carts)

- 48V 100Ah (Discharge 150A for Golf Carts)

- 48V 100Ah (Discharge 200A for Golf Carts)

- 48V 150Ah (for Golf Carts)

- 48V 160Ah (Discharge 100A for Golf Carts)

- 48V 160Ah (Discharge 160A for Golf Carts)

-

48V LiFePO4 Battery

- 60V Lithium Battery

-

60V LiFePO4 Battery

- 60V 20Ah

- 60V 30Ah

- 60V 50Ah

- 60V 50Ah (Small Size / Side Terminal)

- 60V 100Ah (for Electric Motocycle, Electric Scooter, LSV, AGV)

- 60V 100Ah (for Forklift, AGV, Electric Scooter, Sweeper)

- 60V 150Ah (E-Motocycle / E-Scooter / E-Tricycle / Tour LSV)

- 60V 200Ah (for Forklift, AGV, Electric Scooter, Sweeper)

-

60V LiFePO4 Battery

- 72V~96V Lithium Battery

- Rack-mounted Lithium Battery

- E-Bike Battery

- All-in-One Home-ESS

- Wall-mount Battery ESS

-

Home-ESS Lithium Battery PowerWall

- 24V 100Ah 2.4kWh PW24100-S PowerWall

- 48V 50Ah 2.4kWh PW4850-S PowerWall

- 48V 50Ah 2.56kWh PW5150-S PowerWall

- 48V 100Ah 5.12kWh PW51100-F PowerWall (IP65)

- 48V 100Ah 5.12kWh PW51100-S PowerWall

- 48V 100Ah 5.12kWh PW51100-H PowerWall

- 48V 200Ah 10kWh PW51200-H PowerWall

- 48V 300Ah 15kWh PW51300-H PowerWall

PowerWall 51.2V 100Ah LiFePO4 Lithium Battery

Highly popular in Asia and Eastern Europe.

CE Certification | Home-ESS -

Home-ESS Lithium Battery PowerWall

- Portable Power Stations

How Does Cell Balancing During Charging Compare to Cell Balancing During Discharging in Battery BMS?

Cell balancing is a critical function within a Battery Management System (BMS), ensuring that all cells within a battery pack maintain equal voltage levels. This process is essential for optimizing battery performance, extending lifespan, and enhancing safety. Understanding the differences between cell balancing during charging and discharging can significantly impact battery health and efficiency.

What is a Battery Management System (BMS) and Its Purpose?

A Battery Management System (BMS) is an electronic system that manages a rechargeable battery by monitoring its state, calculating its data, reporting that data, and controlling its environment. The primary purpose of a BMS includes:

- Protection: Preventing overcharging, over-discharging, and overheating.

- Balancing: Ensuring all cells within the battery pack are charged and discharged evenly.

- Monitoring: Keeping track of voltage, current, temperature, and state of charge (SoC).

| Function | Description |

|---|---|

| Protection | Prevents damage to the battery from extreme conditions |

| Balancing | Ensures equal voltage across all cells |

| Monitoring | Tracks key metrics for optimal performance |

How Does Cell Balancing Function in a BMS?

Cell balancing involves adjusting the voltage levels of individual cells within a battery pack to ensure they remain at similar states of charge. This can be achieved through two primary methods:

- Passive Balancing: Excess energy from higher-voltage cells is dissipated as heat using resistors.

- Active Balancing: Energy is transferred from higher-voltage cells to lower-voltage cells, improving overall efficiency.

| Method | Description |

|---|---|

| Passive Balancing | Dissipates excess energy as heat |

| Active Balancing | Transfers energy between cells |

Why is Cell Balancing Crucial During the Charging Process?

During charging, some cells may reach their maximum voltage before others due to slight variations in capacity or internal resistance. If not balanced, this can lead to:

- Overcharging: Cells that reach full charge first may become damaged.

- Reduced Capacity: Overall capacity of the battery pack can decrease if some cells are consistently overcharged or undercharged.

Effective cell balancing during charging ensures that all cells reach their full potential without exceeding safe voltage limits.

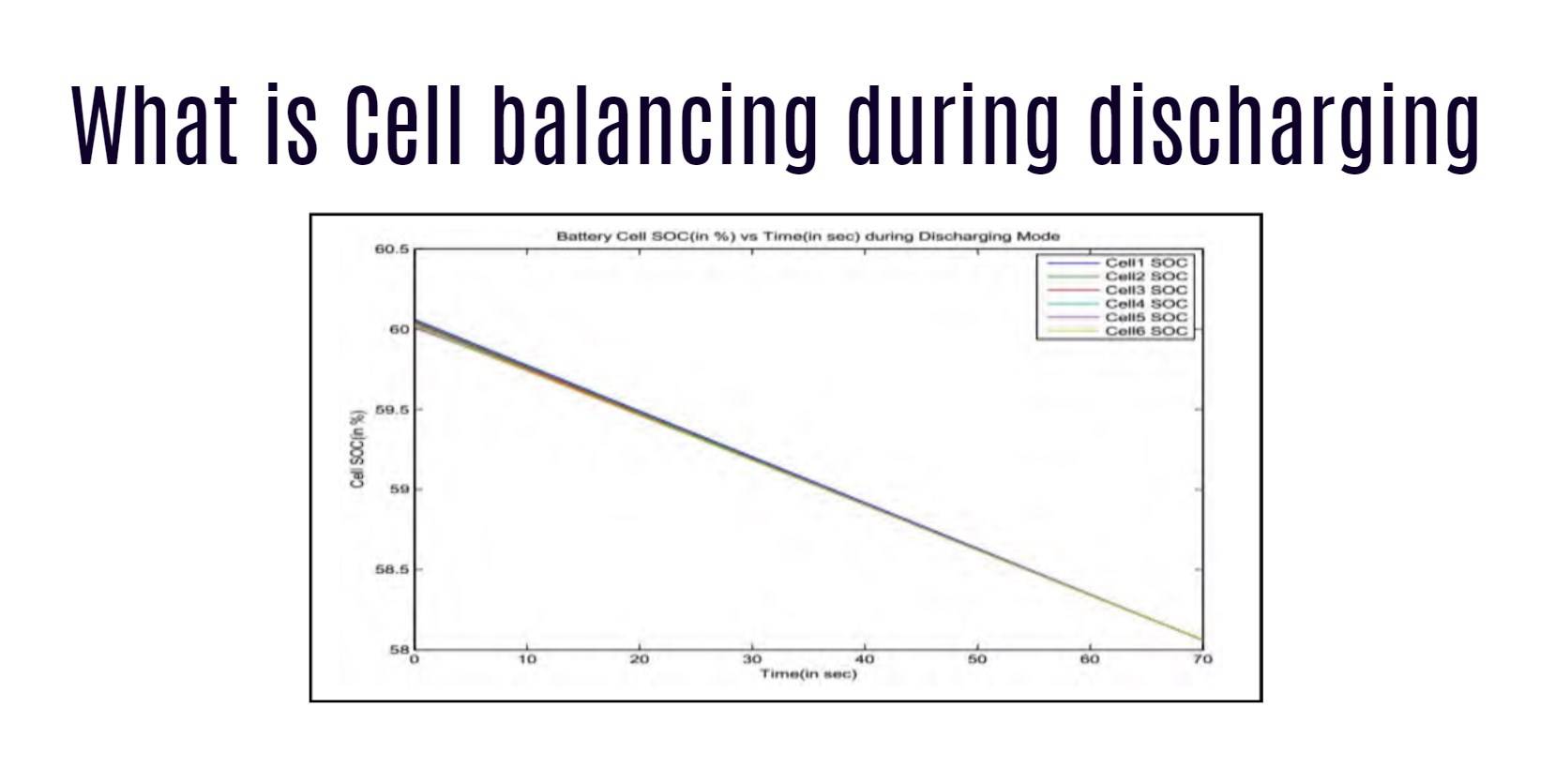

What Role Does Cell Balancing Play During Discharging?

During discharging, cell balancing helps maintain performance by ensuring that no single cell discharges too quickly or deeply compared to others. This process prevents:

- Cell Damage: Over-discharging can lead to irreversible damage.

- Voltage Sag: Uneven discharge can cause voltage drops, affecting device performance.

Balancing during discharging allows for more efficient use of the stored energy, enhancing overall battery life.

How Do Charging and Discharging Affect Battery Health Differently?

Charging and discharging processes affect battery health in distinct ways:

- Charging:

- Focuses on maximizing capacity without exceeding safe limits.

- Requires careful monitoring to prevent overvoltage conditions.

- Discharging:

- Concentrates on maintaining even discharge rates across all cells.

- Aims to prevent deep discharges that can harm individual cells.

Both processes require effective balancing strategies to ensure long-term health and performance.

What are the Best Practices for Effective Cell Balancing in Both Processes?

To achieve optimal cell balancing during charging and discharging:

- Implement Advanced BMS Technology: Use systems that support active balancing for better efficiency.

- Regular Monitoring: Continuously track cell voltages and temperatures to identify imbalances early.

- Scheduled Maintenance: Perform regular checks on battery health and BMS functionality.

Industrial News

Recent advancements in battery technology emphasize the importance of effective cell balancing within Battery Management Systems (BMS). Companies are developing more sophisticated algorithms and hardware solutions that enhance both passive and active balancing methods, leading to improved battery performance and longevity. These innovations are particularly relevant in electric vehicles (EVs) and renewable energy storage systems where efficiency is paramount.

Redway Power Views

“Cell balancing is crucial for maximizing battery life and efficiency,” states an expert from Redway Power. “Understanding how these processes differ during charging and discharging allows manufacturers and users alike to implement better management strategies that enhance safety and performance.”

FAQ Section

Q: What happens if cell balancing is not performed?

A: Without proper cell balancing, batteries can suffer from reduced capacity, shorter lifespan, and increased risk of failure due to overcharging or over-discharging.Q: Can cell balancing be done manually?

A: While some systems allow manual adjustments, effective cell balancing typically requires automated systems integrated into the BMS for real-time monitoring and adjustments.Q: How often should I check my battery’s balance?

A: Regular monitoring during charging cycles is recommended, especially for high-capacity batteries used in demanding applications like electric vehicles or renewable energy systems.