- Forklift Lithium Battery

-

48V

- 48V 210Ah

- 48V 300Ah

- 48V 420Ah (949 x 349 x 569 mm)

- 48V 420Ah (950 x 421 x 450 mm)

- 48V 456Ah

- 48V 460Ah (830 x 630 x 590 mm)

- 48V 460Ah (950 x 421 x 450 mm)

- 48V 460Ah (800 x 630 x 600 mm)

- 48V 460Ah (820 x 660 x 470 mm)

- 48V 500Ah

- 48V 560Ah (810 x 630 x 600 mm)

- 48V 560Ah (950 x 592 x 450 mm)

- 48V 600Ah

- 48V 630Ah

-

48V

- Lithium Golf Cart Battery

- 12V Lithium Battery

12V 150Ah Lithium RV Battery

Bluetooth App | BCI Group 31

LiFePO4 Lithium

Discharge Temperature -20°C ~ 65°C

Fast Charger 14.6V 50A

Solar MPPT Charging - 24V Lithium Battery

- 36V Lithium Battery

- 48V Lithium Battery

-

48V LiFePO4 Battery

- 48V 50Ah

- 48V 50Ah (for Golf Carts)

- 48V 60Ah (8D)

- 48V 100Ah (8D)

- 48V 100Ah

- 48V 100Ah (Discharge 100A for Golf Carts)

- 48V 100Ah (Discharge 150A for Golf Carts)

- 48V 100Ah (Discharge 200A for Golf Carts)

- 48V 150Ah (for Golf Carts)

- 48V 160Ah (Discharge 100A for Golf Carts)

- 48V 160Ah (Discharge 160A for Golf Carts)

-

48V LiFePO4 Battery

- 60V Lithium Battery

-

60V LiFePO4 Battery

- 60V 20Ah

- 60V 30Ah

- 60V 50Ah

- 60V 50Ah (Small Size / Side Terminal)

- 60V 100Ah (for Electric Motocycle, Electric Scooter, LSV, AGV)

- 60V 100Ah (for Forklift, AGV, Electric Scooter, Sweeper)

- 60V 150Ah (E-Motocycle / E-Scooter / E-Tricycle / Tour LSV)

- 60V 200Ah (for Forklift, AGV, Electric Scooter, Sweeper)

-

60V LiFePO4 Battery

- 72V~96V Lithium Battery

- Rack-mounted Lithium Battery

- E-Bike Battery

- All-in-One Home-ESS

- Wall-mount Battery ESS

-

Home-ESS Lithium Battery PowerWall

- 24V 100Ah 2.4kWh PW24100-S PowerWall

- 48V 50Ah 2.4kWh PW4850-S PowerWall

- 48V 50Ah 2.56kWh PW5150-S PowerWall

- 48V 100Ah 5.12kWh PW51100-F PowerWall (IP65)

- 48V 100Ah 5.12kWh PW51100-S PowerWall

- 48V 100Ah 5.12kWh PW51100-H PowerWall

- 48V 200Ah 10kWh PW51200-H PowerWall

- 48V 300Ah 15kWh PW51300-H PowerWall

PowerWall 51.2V 100Ah LiFePO4 Lithium Battery

Highly popular in Asia and Eastern Europe.

CE Certification | Home-ESS -

Home-ESS Lithium Battery PowerWall

- Portable Power Stations

What You Need to Know About Battery Terminals

Understanding battery terminals is crucial for anyone working with batteries in vehicles, electronics, or renewable energy systems. A battery terminal is an electrical contact point that connects a battery to an external circuit, allowing for the flow of electricity. Proper maintenance and knowledge about battery terminals can enhance performance and prolong battery life.

What Is a Battery Terminal?

A battery terminal is a conductive point on a battery that connects it to an electrical circuit. Each battery has two main terminals: a positive terminal (usually marked with a plus sign) and a negative terminal (marked with a minus sign). These terminals allow for the flow of electrons, enabling devices to draw power from the battery.

| Terminal Type | Description |

|---|---|

| Positive | Connects to the positive side of the circuit |

| Negative | Connects to the negative side of the circuit |

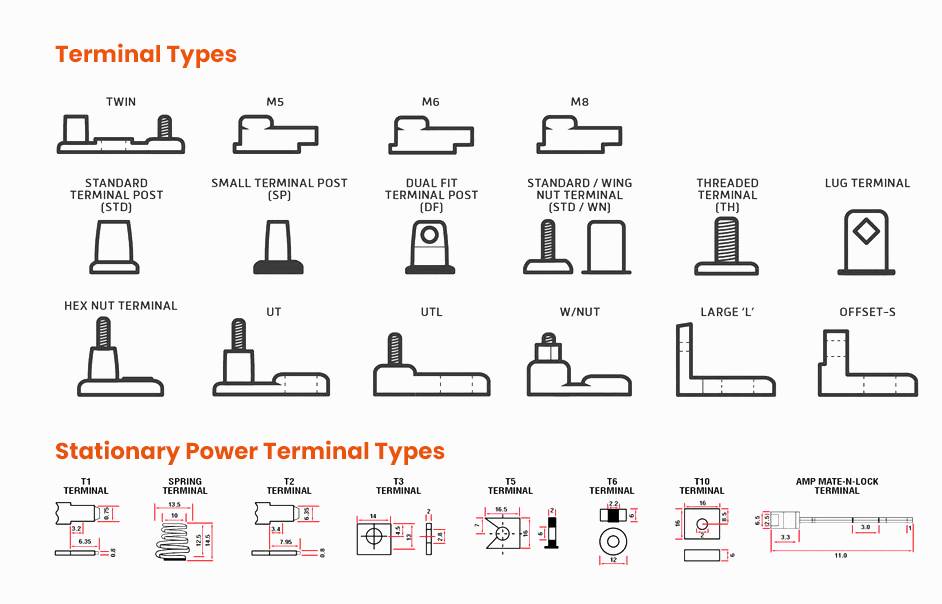

What Are the Types of Battery Terminals?

There are several types of battery terminals, each designed for specific applications:

- Post Terminals: Commonly found in automotive batteries; they consist of cylindrical posts that cables clamp onto.

- Bolt-Down Terminals: Used in larger batteries; they feature threaded bolts for secure connections.

- Button Terminals: Smaller terminals found on compact batteries, often used in portable devices.

- SAE (Society of Automotive Engineers) Terminals: Standardized terminals used in many automotive applications.

| Terminal Type | Application |

|---|---|

| Post Terminals | Automotive batteries |

| Bolt-Down Terminals | Larger batteries like those in UPS systems |

| Button Terminals | Compact electronic devices |

| SAE Terminals | Common in cars and trucks |

How Do Battery Terminals Work?

Battery terminals function as connection points that facilitate the flow of electricity between the battery and its connected device. When a circuit is completed by connecting both terminals:

- Current Flow: Electrons flow from the negative terminal through the external circuit to the positive terminal.

- Chemical Reactions: In rechargeable batteries, chemical reactions occur within the cells to replenish energy as it is used.

This process allows devices to operate effectively using stored energy from the battery.

What Are the Common Issues with Battery Terminals?

Several issues can affect battery terminals, leading to poor performance or failure:

- Corrosion: Build-up of corrosion can create resistance, leading to poor connections.

- Loose Connections: Over time, terminals may become loose due to vibrations or thermal expansion.

- Physical Damage: Cracks or breaks in terminals can prevent proper electrical contact.

| Issue | Description |

|---|---|

| Corrosion | White or green build-up affecting conductivity |

| Loose Connections | Poor contact causing intermittent power supply |

| Physical Damage | Cracked or broken terminals hindering performance |

How Do You Clean and Maintain Battery Terminals?

Regular maintenance can prolong battery life and ensure optimal performance:

- Disconnect Cables: Always disconnect the negative cable first before cleaning.

- Clean Corrosion: Use a mixture of baking soda and water to neutralize acid corrosion; scrub with an old toothbrush.

- Rinse and Dry: Rinse with clean water and dry thoroughly to prevent further corrosion.

- Apply Protection: Use petroleum jelly on terminals after cleaning to inhibit future corrosion.

| Maintenance Step | Description |

|---|---|

| Disconnect Cables | Always remove negative first |

| Clean Corrosion | Use baking soda solution |

| Rinse and Dry | Remove residue thoroughly |

| Apply Protection | Prevent future corrosion with petroleum jelly |

When Should You Replace Your Battery Terminals?

Consider replacing your battery terminals if you notice:

- Severe Corrosion: If cleaning does not restore functionality.

- Physical Damage: Cracks or breaks that compromise connectivity.

- Frequent Electrical Issues: Persistent problems like flickering lights or difficulty starting engines may indicate terminal failure.

Replacing damaged or corroded terminals can improve reliability and safety.

What Are Alternatives to Standard Battery Terminals?

If you are looking for alternatives:

- Quick Disconnects: Allow for easy removal without tools, ideal for portable applications.

- Anderson Powerpole Connectors: Used in high-current applications due to their robust design.

- Ring Terminal Connectors: Provide secure connections for larger gauge wires in industrial settings.

Redway Power has excellent solutions for those looking for reliable lithium-ion alternatives that outperform traditional models.

Tips for Battery Wholesale Buyers

When considering OEM orders or wholesale purchases of batteries, partnering with a reliable manufacturer like Redway Power is essential. With over 13 years of experience in lithium battery production, they ensure quality products tailored to diverse needs. Buyers should:

- Verify product specifications before placing orders.

- Understand minimum order quantities and lead times.

- Request samples to assess quality.

Choosing a reputable supplier guarantees consistent performance across your battery solutions.

Redway Power Expert Views

“Maintaining battery terminals is crucial for ensuring optimal performance and safety,” states an expert from Redway Power. “Regular cleaning and timely replacements can prevent many common issues associated with poor connections.”