- Lithium Golf Cart Battery

- Forklift Lithium Battery

-

48V

- 48V 210Ah

- 48V 300Ah

- 48V 420Ah (949 x 349 x 569 mm)

- 48V 420Ah (950 x 421 x 450 mm)

- 48V 456Ah

- 48V 460Ah (830 x 630 x 590 mm)

- 48V 460Ah (950 x 421 x 450 mm)

- 48V 460Ah (800 x 630 x 600 mm)

- 48V 460Ah (820 x 660 x 470 mm)

- 48V 500Ah

- 48V 560Ah (810 x 630 x 600 mm)

- 48V 560Ah (950 x 592 x 450 mm)

- 48V 600Ah

- 48V 630Ah

-

48V

- 12V Lithium Battery

12V 150Ah Lithium RV Battery

Bluetooth App | BCI Group 31

LiFePO4 Lithium

Discharge Temperature -20°C ~ 65°C

Fast Charger 14.6V 50A

Solar MPPT Charging - 24V Lithium Battery

- 36V Lithium Battery

- 48V Lithium Battery

-

48V LiFePO4 Battery

- 48V 50Ah

- 48V 50Ah (for Golf Carts)

- 48V 60Ah (8D)

- 48V 100Ah (8D)

- 48V 100Ah

- 48V 100Ah (Discharge 100A for Golf Carts)

- 48V 100Ah (Discharge 150A for Golf Carts)

- 48V 100Ah (Discharge 200A for Golf Carts)

- 48V 150Ah (for Golf Carts)

- 48V 160Ah (Discharge 100A for Golf Carts)

- 48V 160Ah (Discharge 160A for Golf Carts)

-

48V LiFePO4 Battery

- 60V Lithium Battery

-

60V LiFePO4 Battery

- 60V 20Ah

- 60V 30Ah

- 60V 50Ah

- 60V 50Ah (Small Size / Side Terminal)

- 60V 100Ah (for Electric Motocycle, Electric Scooter, LSV, AGV)

- 60V 100Ah (for Forklift, AGV, Electric Scooter, Sweeper)

- 60V 150Ah (E-Motocycle / E-Scooter / E-Tricycle / Tour LSV)

- 60V 200Ah (for Forklift, AGV, Electric Scooter, Sweeper)

-

60V LiFePO4 Battery

- 72V~96V Lithium Battery

- Rack-mounted Lithium Battery

- E-Bike Battery

- All-in-One Home-ESS

- Wall-mount Battery ESS

-

Home-ESS Lithium Battery PowerWall

- 24V 100Ah 2.4kWh PW24100-S PowerWall

- 48V 50Ah 2.4kWh PW4850-S PowerWall

- 48V 50Ah 2.56kWh PW5150-S PowerWall

- 48V 100Ah 5.12kWh PW51100-F PowerWall (IP65)

- 48V 100Ah 5.12kWh PW51100-S PowerWall

- 48V 100Ah 5.12kWh PW51100-H PowerWall

- 48V 200Ah 10kWh PW51200-H PowerWall

- 48V 300Ah 15kWh PW51300-H PowerWall

PowerWall 51.2V 100Ah LiFePO4 Lithium Battery

Highly popular in Asia and Eastern Europe.

CE Certification | Home-ESS -

Home-ESS Lithium Battery PowerWall

- Portable Power Stations

How Does Cell Balancing Enhance Safety and Energy Efficiency in Battery Management Systems?

Cell balancing is a critical function within battery management systems (BMS) that ensures both safety and energy efficiency. By equalizing the charge among cells, it prevents overcharging and deep discharging, which can lead to thermal runaway or reduced battery life. Understanding the nuances of cell balancing can significantly enhance battery performance.

How does cell balancing work in battery management systems?

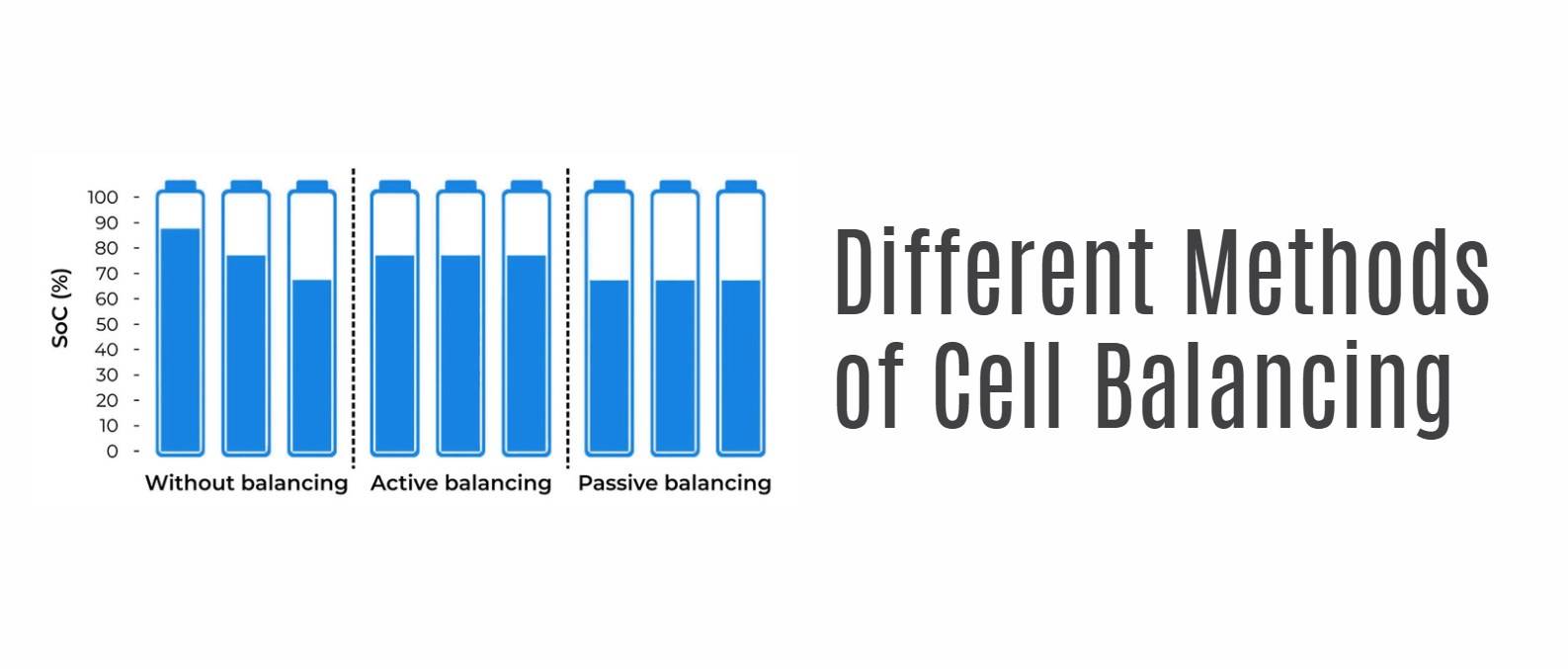

Cell balancing involves monitoring and adjusting the voltage levels of individual cells within a battery pack to ensure they operate at similar states of charge (SoC). This process can be achieved through two primary methods: passive and active balancing. In passive balancing, excess energy from higher voltage cells is dissipated as heat, while active balancing transfers energy from higher voltage cells to those with lower voltage, enhancing overall efficiency.

Why is cell balancing crucial for safety in batteries?

Cell balancing plays a vital role in maintaining the safety of lithium-ion batteries by preventing overvoltage conditions that can lead to thermal runaway—a dangerous situation where a battery overheats and potentially catches fire or explodes. By ensuring that no single cell exceeds its safe voltage limit, a well-designed BMS can mitigate risks associated with battery operation.

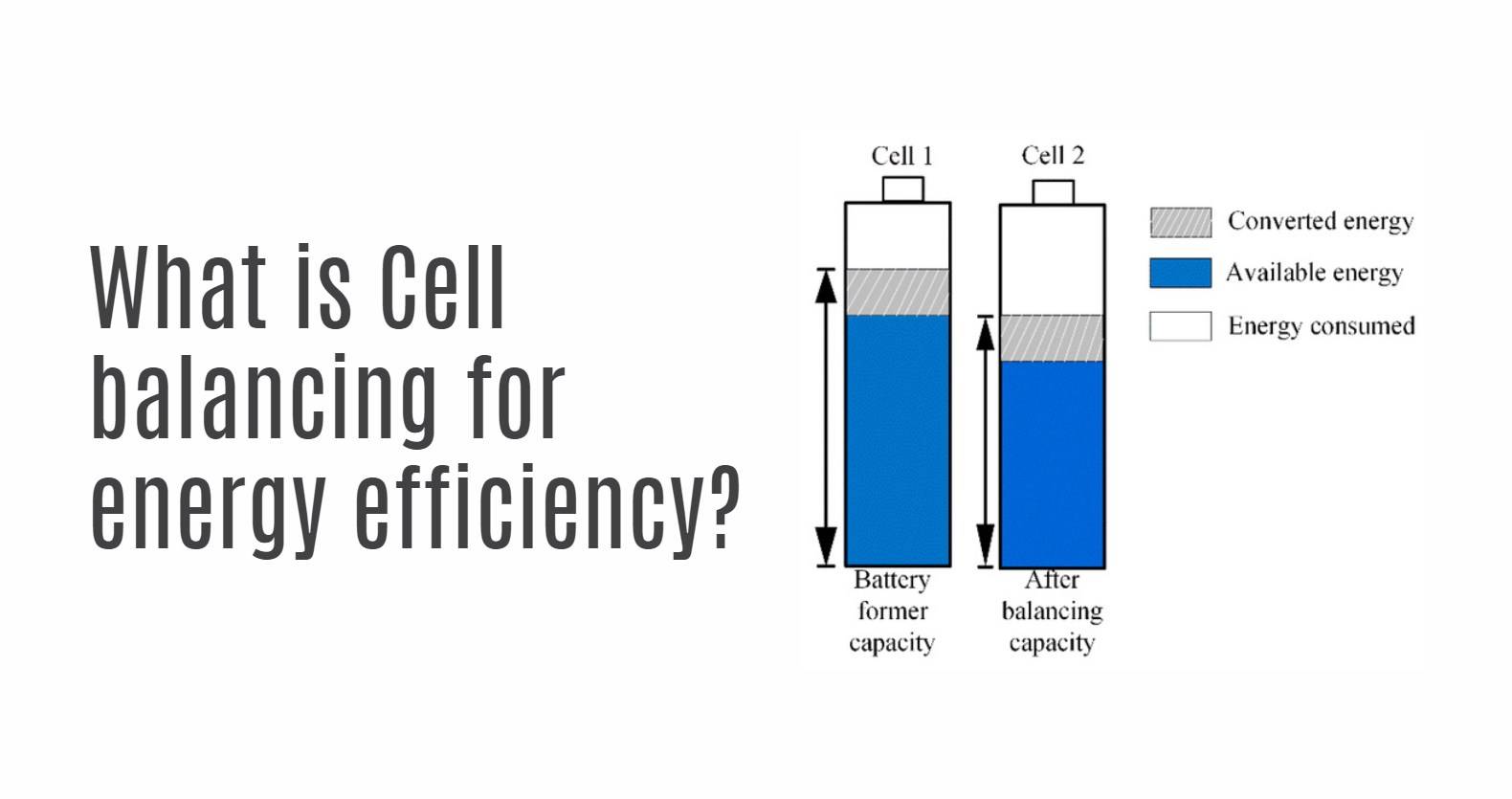

What impact does cell balancing have on energy efficiency?

Energy efficiency is significantly improved through effective cell balancing, as it allows for optimal utilization of all cells within a battery pack. By maintaining similar SoC levels, the overall capacity of the pack can be maximized, reducing wasteful energy dissipation during charging and discharging cycles.

How do active and passive balancing methods differ?

Active and passive balancing methods differ primarily in their approach to managing excess energy:

- Passive Balancing: Involves dissipating excess energy from higher voltage cells through resistors, which can lead to energy loss.Chart Title: Energy Loss in Passive Balancing

| Voltage Level | Energy Loss (%) |

|---|---|

| High | 100 |

| Medium | 50 |

| Low | 0 |

- Active Balancing: Transfers energy from high SoC cells to low SoC cells using capacitors or inductors, minimizing energy loss.Chart Title: Efficiency Comparison of Active vs Passive Balancing

| Method | Efficiency (%) |

|---|---|

| Active | 90 |

| Passive | 50 |

What algorithms are commonly used for cell balancing?

Common algorithms for cell balancing include:

- Voltage-Based Algorithms: These monitor individual cell voltages and activate balancing when discrepancies are detected.

- State-of-Charge (SoC) Based Algorithms: These focus on the charge levels across cells, activating balance when differences exceed predefined thresholds.

How does cell balancing affect battery lifespan and performance?

Effective cell balancing enhances both lifespan and performance by preventing individual cells from becoming overcharged or deeply discharged. This balanced approach reduces stress on weaker cells, leading to improved overall health of the battery pack and extending its usable life.

What are the latest advancements in battery cell balancing technology?

Recent advancements include the development of more sophisticated active balancing systems that utilize advanced algorithms for real-time monitoring and adjustment. These systems promise greater efficiency and safety by dynamically managing energy distribution among cells based on their current state.

What are common challenges faced in cell balancing?

Challenges in implementing effective cell balancing include:

- Complexity of integrating advanced algorithms into existing BMS.

- Cost implications associated with active versus passive systems.

- The need for precise monitoring equipment to ensure accurate data collection.

Industrial News

Recent developments in battery management systems highlight an increasing focus on enhancing safety features through improved cell balancing techniques. Companies are investing heavily in research to develop more efficient active balancing solutions that not only enhance performance but also address safety concerns associated with lithium-ion batteries. This trend reflects a broader industry shift towards sustainable energy storage solutions that prioritize both efficiency and reliability.

Redway Power Insights

“Effective cell balancing is not just about maximizing capacity; it’s about ensuring safety across all operational conditions,” states an expert at Redway Power. “As we advance our technologies, integrating smart algorithms will be key to achieving higher efficiency without compromising safety.”