- Forklift Lithium Battery

-

48V

- 48V 210Ah

- 48V 300Ah

- 48V 420Ah (949 x 349 x 569 mm)

- 48V 420Ah (950 x 421 x 450 mm)

- 48V 456Ah

- 48V 460Ah (830 x 630 x 590 mm)

- 48V 460Ah (950 x 421 x 450 mm)

- 48V 460Ah (800 x 630 x 600 mm)

- 48V 460Ah (820 x 660 x 470 mm)

- 48V 500Ah

- 48V 560Ah (810 x 630 x 600 mm)

- 48V 560Ah (950 x 592 x 450 mm)

- 48V 600Ah

- 48V 630Ah

-

48V

- Lithium Golf Cart Battery

- 12V Lithium Battery

12V 150Ah Lithium RV Battery

Bluetooth App | BCI Group 31

LiFePO4 Lithium

Discharge Temperature -20°C ~ 65°C

Fast Charger 14.6V 50A

Solar MPPT Charging - 24V Lithium Battery

- 36V Lithium Battery

- 48V Lithium Battery

-

48V LiFePO4 Battery

- 48V 50Ah

- 48V 50Ah (for Golf Carts)

- 48V 60Ah (8D)

- 48V 100Ah (8D)

- 48V 100Ah

- 48V 100Ah (Discharge 100A for Golf Carts)

- 48V 100Ah (Discharge 150A for Golf Carts)

- 48V 100Ah (Discharge 200A for Golf Carts)

- 48V 150Ah (for Golf Carts)

- 48V 160Ah (Discharge 100A for Golf Carts)

- 48V 160Ah (Discharge 160A for Golf Carts)

-

48V LiFePO4 Battery

- 60V Lithium Battery

-

60V LiFePO4 Battery

- 60V 20Ah

- 60V 30Ah

- 60V 50Ah

- 60V 50Ah (Small Size / Side Terminal)

- 60V 100Ah (for Electric Motocycle, Electric Scooter, LSV, AGV)

- 60V 100Ah (for Forklift, AGV, Electric Scooter, Sweeper)

- 60V 150Ah (E-Motocycle / E-Scooter / E-Tricycle / Tour LSV)

- 60V 200Ah (for Forklift, AGV, Electric Scooter, Sweeper)

-

60V LiFePO4 Battery

- 72V~96V Lithium Battery

- Rack-mounted Lithium Battery

- E-Bike Battery

- All-in-One Home-ESS

- Wall-mount Battery ESS

-

Home-ESS Lithium Battery PowerWall

- 24V 100Ah 2.4kWh PW24100-S PowerWall

- 48V 50Ah 2.4kWh PW4850-S PowerWall

- 48V 50Ah 2.56kWh PW5150-S PowerWall

- 48V 100Ah 5.12kWh PW51100-F PowerWall (IP65)

- 48V 100Ah 5.12kWh PW51100-S PowerWall

- 48V 100Ah 5.12kWh PW51100-H PowerWall

- 48V 200Ah 10kWh PW51200-H PowerWall

- 48V 300Ah 15kWh PW51300-H PowerWall

PowerWall 51.2V 100Ah LiFePO4 Lithium Battery

Highly popular in Asia and Eastern Europe.

CE Certification | Home-ESS -

Home-ESS Lithium Battery PowerWall

- Portable Power Stations

How Do I Properly Maintain and Restore My Lead-Acid Battery?

Proper maintenance and restoration of lead-acid batteries can significantly extend their lifespan and enhance performance. Lead-acid batteries typically last between 3 to 5 years, but with regular testing and maintenance, you can maximize their efficiency and reliability. This guide covers essential practices for maintaining and restoring your lead-acid battery.

What are lead-acid batteries and how do they work?

Lead-acid batteries are rechargeable batteries that use lead dioxide (PbO2) as the positive plate, sponge lead (Pb) as the negative plate, and sulfuric acid (H2SO4) as the electrolyte. The basic operation involves:

- Discharge: During use, chemical reactions convert chemical energy into electrical energy.

- Charge: When recharged, electrical energy converts back into chemical energy, restoring the battery’s capacity.

Chart: Basic Components of Lead-Acid Batteries

| Component | Function |

|---|---|

| Positive Plate | Made of lead dioxide; facilitates oxidation |

| Negative Plate | Made of sponge lead; facilitates reduction |

| Electrolyte | Sulfuric acid; conducts ions between plates |

How can I test the health of my lead-acid battery?

Testing your battery’s health is crucial for identifying potential issues:

- Voltage Test: Use a multimeter to measure the resting voltage. A healthy battery should read around 12.6 to 12.8 volts.

- Hydrometer Test: For flooded batteries, a hydrometer can measure specific gravity, indicating charge levels.

- Load Test: Apply a load to see how well the battery holds voltage under stress.

What are the common maintenance practices for lead-acid batteries?

Regular maintenance helps ensure optimal performance:

- Check Electrolyte Levels: Ensure levels are above the plates; add distilled water if necessary.

- Clean Terminals: Remove corrosion with a mixture of baking soda and water.

- Inspect Connections: Ensure all connections are tight and free from corrosion.

Chart: Maintenance Tasks for Lead-Acid Batteries

| Task | Frequency | Purpose |

|---|---|---|

| Check Electrolyte Levels | Monthly | Prevents sulfation and ensures performance |

| Clean Terminals | Every 3 months | Ensures good electrical connection |

| Inspect Connections | Monthly | Prevents voltage drops due to poor contact |

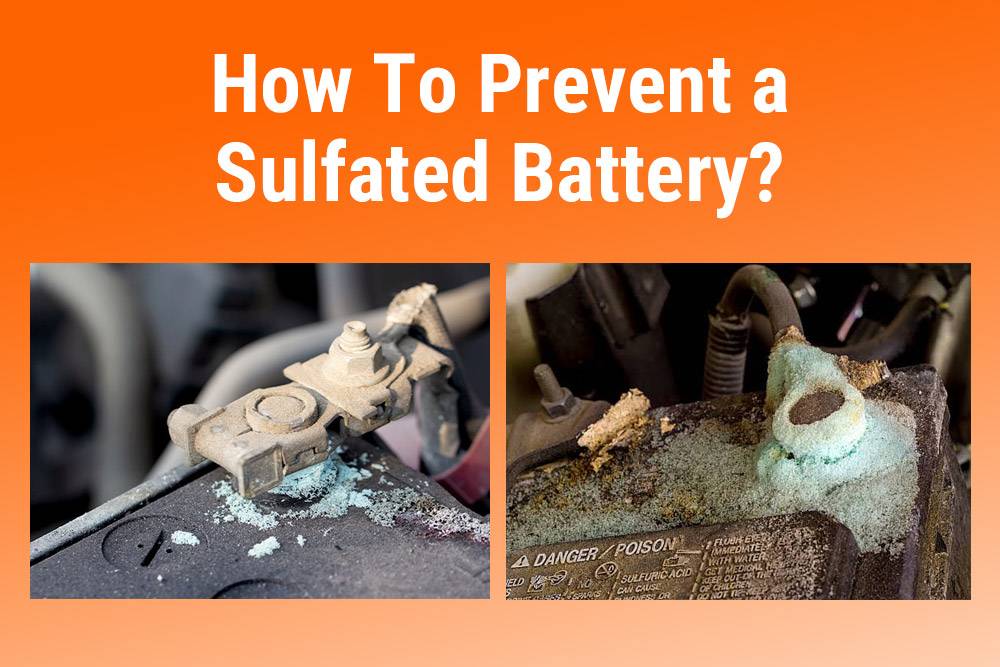

How can I restore a lead-acid battery?

Restoring a lead-acid battery can rejuvenate its performance:

- Equalization Charging: This controlled overcharge helps break down sulfation on plates.

- Desulfation Devices: These devices or additives help dissolve sulfate crystals that accumulate over time.

- Regular Cycling: Fully discharging and recharging can help maintain capacity.

What types of lead-acid batteries are available?

There are several types of lead-acid batteries:

- Flooded Lead-Acid Batteries: Require regular maintenance; electrolyte levels must be checked frequently.

- Absorbed Glass Mat (AGM): Sealed design; maintenance-free and less prone to spills.

- Gel Batteries: Use a gelled electrolyte; safe for various applications but sensitive to charging conditions.

What factors affect the lifespan of lead-acid batteries?

Several factors influence how long a lead-acid battery lasts:

- Temperature: Extreme heat or cold can accelerate degradation.

- Charging Practices: Overcharging or undercharging can reduce lifespan significantly.

- Usage Patterns: Frequent deep discharges can shorten overall life.

When should I replace my lead-acid battery?

Consider replacing your battery if you notice:

- Voltage Drops Below 12 volts: Indicates it may not hold a charge effectively.

- Physical Damage or Swelling: Signs of internal failure or damage.

- Frequent Charging Needs: If you find yourself needing to recharge often, it may be time for a replacement.

Industrial News

The market for lead-acid batteries continues to evolve with advancements in technology aimed at improving efficiency and sustainability. Manufacturers are increasingly focusing on developing longer-lasting, maintenance-free options such as AGM and gel batteries, which cater to consumer demands for convenience without sacrificing performance.

Redway Power Insights

“Understanding how to maintain and restore your lead-acid battery is essential for maximizing its lifespan,” states an expert from Redway Power. “With proper care, these batteries can provide reliable service for many years, making them a valuable investment.”

FAQ Section

How long do lead-acid batteries typically last?

Lead-acid batteries generally last between 3 to 5 years with proper care.What should I do if my battery shows signs of sulfation?

Consider equalization charging or using desulfation devices to restore capacity.How often should I check my battery’s electrolyte levels?

It’s recommended to check electrolyte levels at least once a month, especially in flooded batteries.