- Rack-mounted Lithium Battery

- Golf Cart Lithium Battery

-

Golf Cart Lithium Battery

- 36V 50Ah (for Golf Carts)

- 36V 80Ah (for Golf Carts)

- 36V 100Ah (for Golf Carts)

- 48V 50Ah (for Golf Carts)

- 48V 100Ah (Discharge 100A for Golf Carts)

- 48V 100Ah (Discharge 150A for Golf Carts)

- 48V 100Ah (Discharge 200A for Golf Carts)

- 48V 120Ah (for Golf Carts)

- 48V 150Ah (for Golf Carts)

- 48V 160Ah (Discharge 100A for Golf Carts)

- 48V 160Ah (Discharge 160A for Golf Carts)

-

Golf Cart Lithium Battery

- Forklift Lithium Battery

- 12V Lithium Battery

- 24V Lithium Battery

- 36V Lithium Battery

- 48V Lithium Battery

-

48V LiFePO4 Battery

- 48V 50Ah

- 48V 50Ah (for Golf Carts)

- 48V 60Ah (8D)

- 48V 100Ah (8D)

- 48V 100Ah

- 48V 100Ah (Discharge 100A for Golf Carts)

- 48V 100Ah (Discharge 150A for Golf Carts)

- 48V 100Ah (Discharge 200A for Golf Carts)

- 48V 150Ah (for Golf Carts)

- 48V 160Ah (Discharge 100A for Golf Carts)

- 48V 160Ah (Discharge 160A for Golf Carts)

-

48V LiFePO4 Battery

- 60V Lithium Battery

-

60V LiFePO4 Battery

- 60V 20Ah

- 60V 30Ah

- 60V 50Ah

- 60V 50Ah (Small Size / Side Terminal)

- 60V 100Ah (for Electric Motocycle, Electric Scooter, LSV, AGV)

- 60V 100Ah (for Forklift, AGV, Electric Scooter, Sweeper)

- 60V 150Ah (E-Motocycle / E-Scooter / E-Tricycle / Tour LSV)

- 60V 200Ah (for Forklift, AGV, Electric Scooter, Sweeper)

-

60V LiFePO4 Battery

- 72V~96V Lithium Battery

- E-Bike Battery

- All-in-One Home-ESS

- Wall-mount Battery ESS

-

Home-ESS Lithium Battery PowerWall

- 24V 100Ah 2.4kWh PW24100-S PowerWall

- 48V 50Ah 2.4kWh PW4850-S PowerWall

- 48V 50Ah 2.56kWh PW5150-S PowerWall

- 48V 100Ah 5.12kWh PW51100-F PowerWall (IP65)

- 48V 100Ah 5.12kWh PW51100-S PowerWall

- 48V 100Ah 5.12kWh PW51100-H PowerWall

- 48V 200Ah 10kWh PW51200-H PowerWall

- 48V 300Ah 15kWh PW51300-H PowerWall

PowerWall 51.2V 100Ah LiFePO4 Lithium Battery

Highly popular in Asia and Eastern Europe.

CE Certification | Home-ESS -

Home-ESS Lithium Battery PowerWall

- Portable Power Stations

AGM vs Flooded Battery, Comprehensive Guide

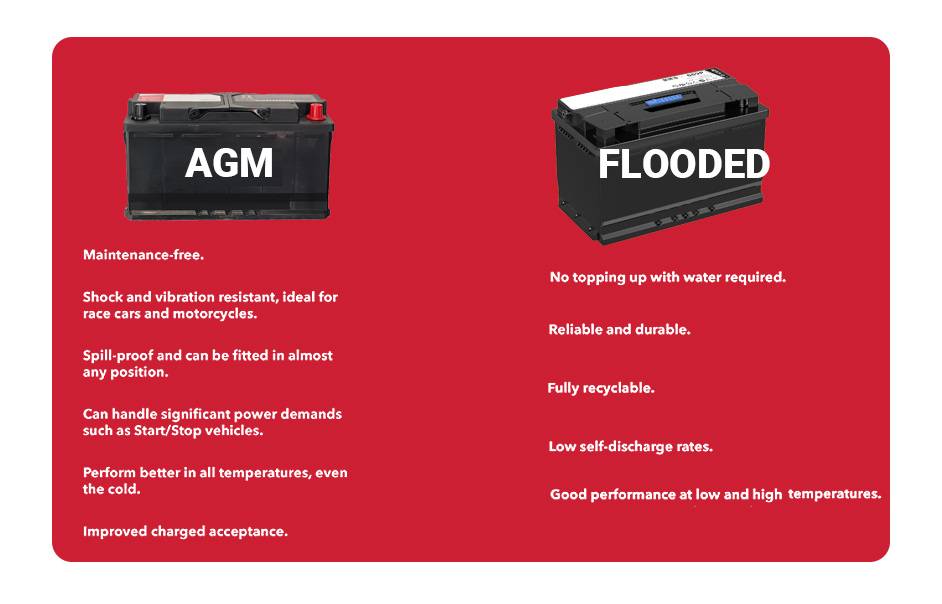

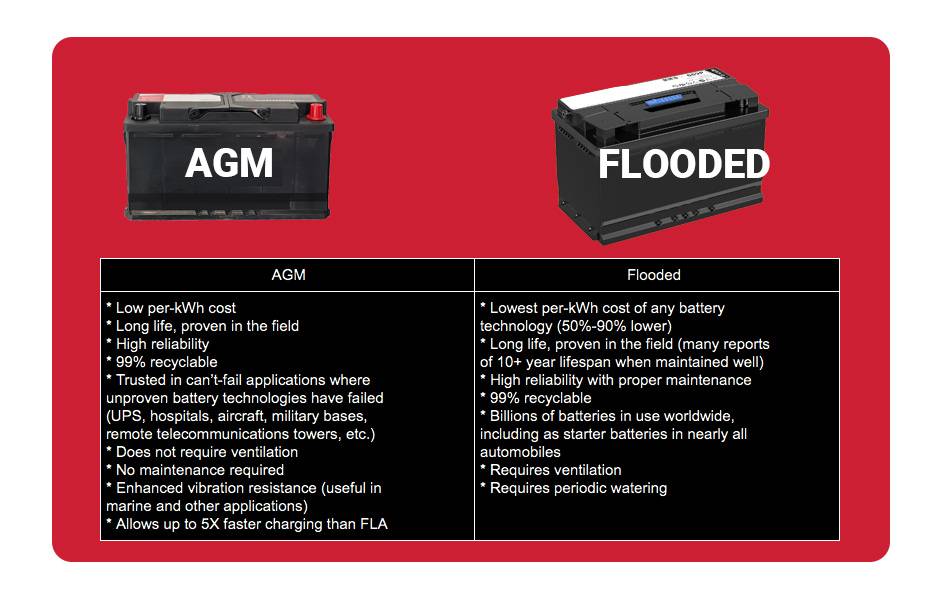

Lead-acid batteries are widely used for vehicles, equipment, and renewable energy systems due to their reliability, durability, and cost-effectiveness. Two common types are Absorbed Glass Mat (AGM) and Flooded batteries. AGM batteries have absorbed electrolyte, making them spill-proof and maintenance-free, ideal for applications needing quick charging. Flooded batteries have free electrolyte and require regular maintenance but are cost-effective. Choose based on specific needs and budget.

Explore the AGM vs Flooded Batteries debate with our concise guide. In the realm of energy storage, AGM (Absorbent Glass Mat) and flooded batteries play crucial roles. This guide highlights the differences, advantages, disadvantages, and maintenance needs, empowering you to make informed decisions. Whether for vehicles or solar systems, discover the right battery for your needs and navigate the intricacies of AGM vs Flooded Batteries.

What is an AGM Battery?

AGM batteries, or Absorbent Glass Mat batteries, stand out for their stellar performance and durability. Here’s a streamlined breakdown of why they might be the ideal choice for your power needs.

1. Efficient Design for Extended Lifespan:

- AGM batteries use a fiberglass mat to secure the electrolyte, promoting efficient oxygen recombination. This not only extends the battery’s lifespan but also eliminates the need for regular water additions, making them hassle-free and maintenance-free.

2. High Current Outputs for Quick Power Bursts:

- A standout feature is AGM batteries’ capability to deliver high current outputs without significant voltage drops. Perfect for applications requiring quick bursts of power, such as starting engines or powering electrical accessories in vehicles.

3. Long-lasting Charge and Resilience:

- AGM batteries boast a lower self-discharge rate, retaining their charge for extended periods when not in use. Their robust construction also makes them resistant to vibration and shock, ideal for demanding environments like marine vessels or off-road vehicles.

In Conclusion, AGM batteries offer a compelling package – minimal maintenance, reliable performance, and durability. Whether for your vehicle or renewable energy system, consider the efficiency and resilience AGM batteries bring to the table for optimal results!

What is a Flooded Battery?

Flooded batteries, also known as wet cells or lead-acid batteries, stand as one of the oldest and most widespread battery types. Dive into the basics to grasp their essence.

1. Core Construction:

- At its heart, a flooded battery comprises lead plates immersed in a water and sulfuric acid electrolyte solution. Multiple cells with positive and negative plates are connected to generate the desired voltage.

2. Maintenance Essentials:

- Regular upkeep is a key consideration with flooded batteries. Due to their design, the liquid electrolyte can evaporate over time. Periodic checks and replenishment are crucial. Additionally, during charging, these batteries may release gases that require safe venting.

3. Affordability and Drawbacks:

- Flooded batteries are valued for their cost-effectiveness and durability, notably in automotive applications. However, they demand proper maintenance as they are prone to damage from factors like vibration or tilting if not securely positioned.

In Essence, Flooded batteries, classic lead-acid workhorses, provide reliability and affordability. Yet, diligent maintenance is the key to unlocking their optimal performance and longevity.

Comparison of AGM and Flooded Batteries

When delving into battery options, the AGM (Absorbent Glass Mat) and flooded batteries emerge as popular contenders. Let’s break down their differences for a clearer understanding.

1. Core Technologies:

- AGM batteries leverage glass mats to secure electrolyte, enhancing resistance to vibration and shock. Meanwhile, flooded batteries feature removable caps, allowing for maintenance and the addition of distilled water as needed.

2. Performance Distinctions:

- AGM batteries typically excel in cranking power, lifespan, faster recharge times, and deep cycling capabilities. On the flip side, flooded batteries are generally more budget-friendly upfront.

3. Maintenance Dynamics:

- AGM batteries demand less maintenance as they eliminate the need for regular distilled water refilling, a task required by flooded batteries. Moreover, AGM batteries are sealed, eliminating the risk of acid spills or leaks.

In Conclusion, The AGM vs. flooded battery decision hinges on specific needs and budget considerations. Opt for AGM if seeking high performance and low maintenance at a higher initial cost. Conversely, choose flooded batteries for affordability, with readiness for regular maintenance tasks. Prioritize factors like usage requirements, cost, and durability when making this crucial battery decision.

Advantages and Disadvantages of AGM and Flooded Batteries

When it comes to AGM (Absorbent Glass Mat) and flooded batteries, understanding their advantages and disadvantages is crucial. Let’s simplify the key points for informed decision-making.

Advantages of AGM Batteries:

- Maintenance-Free Design: AGM batteries eliminate the need for regular electrolyte checks and water refills, offering hassle-free operation.

- Vibration Resistance: With higher resistance to vibration, AGM batteries excel in vehicles or equipment subjected to constant motion or rough terrain.

- Lower Self-Discharge: AGM batteries can hold their charge for extended periods without use, ensuring reliability.

Disadvantages of AGM Batteries:

- Higher Cost: The advanced technology in AGM construction contributes to a higher upfront cost.

- Prolonged High-Current Draw: While offering high power output, AGM batteries may not sustain prolonged high-current draw situations as effectively as flooded batteries.

Advantages of Flooded Batteries:

- Affordability: Flooded batteries remain budget-friendly, making them a popular choice.

- Longer Lifespan: Properly maintained flooded batteries typically exhibit longer lifespans compared to AGM counterparts.

Disadvantages of Flooded Batteries:

- Maintenance Requirements: Regular electrolyte checks and water refills are essential for flooded batteries.

- Potential for Acid Leaks: Mishandling can lead to acid leaks or spills, requiring careful handling.

In Conclusion: The choice between AGM and flooded batteries hinges on specific needs. While AGM batteries offer maintenance-free and vibration-resistant benefits, flooded batteries provide affordability and longer lifespans with proper maintenance. Consider factors like cost, maintenance requirements, and performance characteristics for an optimal battery decision.

Which One Should You Choose?

When deciding between AGM (Absorbent Glass Mat) and flooded batteries, key considerations impact the suitability of each for your needs. Let’s break down the essential factors to simplify your decision-making.

AGM Batteries:

- Maintenance-Free Operation: AGM batteries require minimal upkeep, making them user-friendly.

- Vibration Resistance: Known for high resistance to vibration, AGM batteries suit applications in motion or rough terrains.

- Longer Lifespan: With an extended lifespan compared to flooded batteries, AGM options offer reliability.

- Faster Recharge Rate: AGM batteries recharge quickly, ensuring prompt availability of power.

- Mounting Flexibility: AGM batteries can be mounted in various positions without the risk of acid leakage.

Flooded Batteries:

- Affordability: Upfront cost is lower for flooded batteries, making them budget-friendly.

- Higher Capacity Options: Flooded batteries offer higher capacity options for applications with increased power demands.

- Widespread Availability: Easily accessible and widely available, flooded batteries simplify replacement processes.

- Regular Maintenance: Regular tasks like checking electrolyte levels and adding distilled water are necessary for flooded batteries.

Considerations for Your Decision:

- Convenience and Durability: If convenience and durability are paramount, AGM batteries with their sealed design and minimal maintenance tasks might be the ideal choice.

- Cost and Control: Opt for flooded batteries if cost is a significant factor and you prefer hands-on control over regular maintenance routines.

In Conclusion: Assess your specific needs, considering factors like budget, desired lifespan, and application demands. Whether prioritizing convenience with AGM or cost control with flooded, make an informed decision based on the advantages discussed above for optimal battery performance.

Maintenance and Care Tips for Both Types of Batteries

To ensure the longevity and optimal performance of AGM and flooded batteries, follow these essential maintenance tips:

Regular Maintenance Steps:

- Regular Inspection: Periodically check for damage, leaks, or corrosion. Early identification of issues is crucial for proactive maintenance.

- Cleaning: Keep battery terminals clean using a mixture of baking soda and water. Ensure terminals are completely dry before reconnecting.

- Charging: Follow manufacturer guidelines for charging to avoid overcharging or undercharging, both of which can lead to damage.

- Equalization (Flooded Batteries): Perform equalization charges for flooded batteries as recommended. This process helps eliminate stratification and extends battery life.

Additional Maintenance Tips:

- Avoid Deep Discharges: Minimize frequent full discharges to extend battery lifespan.

- Temperature Control: Operate batteries within specified temperature ranges for optimal performance.

- Proper Ventilation (Flooded Batteries): Ensure adequate ventilation for indoor flooded battery systems to prevent hydrogen gas buildup.

- Regular Testing: Periodically test batteries using a multimeter or voltmeter to check voltage levels and overall health.

Conclusion: Each battery type has unique maintenance requirements. Always refer to the manufacturer’s guidelines for specific instructions tailored to your battery model. Consistent attention to these maintenance steps will contribute to prolonged battery life and reliable performance.

FAQs

What is the composition of AGM batteries that might influence their performance compared to traditional lead-acid batteries?

AGM (Absorbent Glass Mat) batteries feature a unique design that sets them apart from traditional lead-acid batteries. Inside an AGM battery, the electrolyte is absorbed in a glass mat separator, which enhances their performance by providing better electrical conductivity and vibration resistance. This composition allows for a spill-proof design, making AGM batteries ideal for use in various orientations without worrying about leaks or maintenance hassles.

Additionally, the tightly packed construction of AGM batteries results in lower internal resistance compared to flooded batteries. This lower resistance translates into quicker charging times and improved efficiency during discharging cycles. The compact layout also enables AGM batteries to deliver consistent power output over extended periods, ensuring reliable performance when you need it most.

The composition of AGM batteries plays a crucial role in enhancing their durability and efficiency when compared to traditional lead-acid counterparts.

Do AGM batteries require different charging processes than traditional lead-acid batteries?

AGM batteries, also known as Absorbent Glass Mat batteries, boast a different charging process compared to traditional lead-acid batteries. These batteries are designed to be charged at a lower voltage and current due to their internal structure. The AGM battery’s composition requires a specific charging profile that is tailored to its needs.

When charging an AGM battery, it is crucial to follow the manufacturer’s recommendations for optimal performance. Overcharging or undercharging can significantly impact the lifespan and efficiency of the battery. Unlike flooded lead-acid batteries, AGM batteries are more sensitive to incorrect charging methods.

To ensure longevity and reliability, it is essential to use a smart charger specifically designed for AGM batteries when recharging them. This specialized charger helps maintain the correct voltage levels during the charging process, maximizing the battery’s potential.

Understanding and adhering to the unique charging requirements of AGM batteries is key in ensuring their durability and effectiveness in various applications.

What are the general perceptions about the charging characteristics of AGM batteries compared to traditional lead-acid batteries?

AGM batteries are often praised for their superior charging characteristics compared to traditional lead-acid batteries. One common perception is that AGM batteries have a faster charge acceptance rate, allowing them to recharge more efficiently and quickly. This can be advantageous in situations where a quick turnaround time is crucial, such as in emergency vehicles or backup power systems.

Another general perception is that AGM batteries are more forgiving when it comes to overcharging. Unlike flooded batteries, which can suffer from irreversible damage if overcharged, AGM batteries tend to handle excessive charging better due to their design and construction. This perceived resilience makes AGM batteries a popular choice for applications where precise control over the charging process may not always be feasible.

Additionally, many users appreciate the fact that AGM batteries typically require less maintenance when it comes to charging routines. The sealed design of AGM batteries minimizes water loss and electrolyte evaporation, reducing the need for frequent topping up with distilled water like traditional lead-acid batteries often demand.

These positive perceptions surrounding the charging characteristics of AGMs contribute to their growing popularity across various industries and applications.

How do AGM batteries handle physical stress compared to traditional lead-acid batteries?

AGM batteries are known for their superior resistance to physical stress compared to traditional lead-acid batteries. The Absorbent Glass Mat design allows the electrolyte to be trapped within glass fiber mats, reducing the risk of spills and leaks during rough handling or vibrations. This makes AGM batteries ideal for off-road vehicles like Jeeps that encounter bumpy terrains regularly.

The robust construction of AGM batteries also helps them withstand shocks and impacts better than traditional lead-acid batteries. Whether it’s extreme temperatures, rough roads, or constant jolts, AGM batteries hold up well under pressure. This durability ensures a longer lifespan and reliable performance even in challenging environments.

So if you’re looking for a battery that can handle the physical demands of off-road adventures without skipping a beat, AGM batteries are definitely worth considering.

Are AGM batteries suitable for off-road vehicle use, such as in a Jeep?

When it comes to choosing between AGM batteries and flooded batteries for off-road vehicle use, such as in a Jeep, the answer is clear. AGM batteries are highly recommended due to their superior performance and durability in rugged conditions. Their ability to handle physical stress, resist vibrations, and provide reliable power make them an ideal choice for off-road adventures.

So next time you’re gearing up for an off-road excursion in your Jeep, consider investing in an AGM battery for peace of mind knowing that your vehicle’s power source can keep up with the demands of the terrain. Make the switch to AGM batteries and elevate your off-road experience today!

More FAQs

When should a flooded or AGM battery be used in different applications?

When selecting between flooded and AGM batteries for various applications, certain factors should be taken into consideration to determine the most suitable battery type.

Flooded batteries are often preferred for applications where cost is a primary concern and regular maintenance can be carried out. These batteries can handle higher discharge rates and provide a higher surge current compared to AGM batteries. As a result, they are suitable for applications that demand high-power output, such as automotive starting, off-grid renewable energy systems, and heavy-duty industrial equipment.

On the other hand, AGM batteries are highly recommended for sealed and maintenance-free setups. They have a lower self-discharge rate in comparison to flooded batteries, allowing them to retain their charge for extended periods when not in use. The presence of a glass mat separator in AGM batteries makes them highly resistant to vibrations and shocks. This feature is particularly advantageous in applications like deep-cycle storage for RVs and boats, backup power systems, renewable energy storage, and UPS systems.

Are AGM batteries safer to use compared to flooded batteries?

AGM batteries are considered safer to use compared to flooded batteries due to their recombination capabilities. These batteries are designed to recombine gases produced during charging, reducing the emission of hazardous gases. This makes AGM batteries a safer option for use in enclosed spaces. Additionally, the sealed design of AGM batteries eliminates the risk of electrolyte leakage and corrosion, enhancing their safety compared to flooded batteries.

What is the construction and maintenance required for flooded batteries?

Flooded batteries, also called wet cell batteries, feature lead plates submerged in a liquid electrolyte solution enclosed by separators. To maintain these batteries, it is crucial to regularly check and replenish the electrolyte levels with distilled water. Additionally, monitoring the electrolyte-specific gravity and implementing periodic equalization charging to combat electrolyte stratification are essential maintenance tasks for ensuring optimal performance and longevity.

How can one determine the right replacement car battery for their vehicle based on power demands and technological requirements?

Determining the right replacement car battery for your vehicle involves considering both power demands and technological requirements. Standard flooded batteries are commonly used in cars, providing the necessary power to start the engine and operate electrical accessories. However, newer technologies like Enhanced Flooded Batteries (EFB) and Absorbed Glass-Mat Batteries (AGM) offer increased power capabilities, making them essential for modern vehicles with higher power demands.

When selecting a replacement car battery, it is crucial to assess the power requirements of your vehicle, particularly if you have added electrical accessories or modifications that demand more power. Enhanced flooded batteries and absorbed glass-mat batteries are rechargeable and designed to support vehicles with greater power needs, making them suitable choices for newer cars.

Therefore, to determine the right replacement car battery based on power demands and technological requirements, consider the power needs of your vehicle and opt for newer technologies like EFB and AGM batteries to ensure optimal performance and longevity.

What are the key differences between Pure Lead AGM Batteries and Alloy AGM Batteries?

Pure Lead AGM Batteries are made of 99.9% pure lead and offer up to twice the battery cycle life compared to flooded batteries. They also boast the fastest recharge times, the slowest self-discharge or shelf life, and are completely sealed with zero water loss.

On the other hand, Alloy AGM Batteries consist of recycled lead combined with alloy metal. While they share similarities with Pure Lead AGM Batteries, they are not as powerful and typically come at a lower cost.

Which types of vehicles are suitable for Standard Flooded Batteries, Enhanced Flooded Batteries (EFB), and Absorbed Glass-mat (AGM) batteries?

Standard Flooded Batteries are suitable for vehicles such as the Toyota Tacoma, Toyota Corolla, and Lexus RX. Enhanced Flooded Batteries (EFB) are commonly used in cars like the start-stop versions of the Fiat 500, Toyota Yaris, and the Ford ECOnetic range. Absorbed Glass-mat (AGM) batteries are compatible with vehicles like the Buick Encore, Jeep Compass, and the Ford F-150.

What are the differences between Absorbed Glass-mat (AGM) and Enhanced Flooded Battery (EFB) technologies?

Absorbed Glass-mat (AGM) and Enhanced Flooded Battery (EFB) technologies are two distinct types of car batteries that offer various advantages based on specific requirements.

EFB batteries are similar to standard flooded batteries but are engineered to be more resilient, capable of storing more energy, and have an extended lifespan. They are known for their durability, energy storage capacity, longer battery life, weatherproofing, start-stop compatibility, and affordability compared to AGM batteries. Examples of vehicles that use EFB batteries include the start-stop models of the Fiat 500, Toyota Yaris, and Ford ECOnetic range.

On the other hand, AGM batteries have become the standard in modern cars due to the increasing power demands of technologies such as entertainment systems, GPS devices, cameras, and plug-in accessories. AGM batteries utilize glass mats to absorb all of the electrolyte, making them spill-proof and ideal for vehicles equipped with AGM batteries. There are variations within AGM batteries, with Pure Lead AGMs being made of 99.9% pure lead offering advanced power and superior battery life, while Alloy AGMs are made from mixed metals and are relatively less powerful and cheaper than Pure Lead AGMs. Pure Lead AGMs boast benefits such as up to two times longer battery cycle life compared to flooded batteries, fastest recharge times, slowest self-discharge rates, and being sealed with zero water loss.

In summary, EFB batteries offer enhanced durability, energy storage, longer lifespan, and affordability, making them suitable for certain vehicle models with start-stop technology. Meanwhile, AGM batteries are preferred for their ability to meet the power demands of modern cars while providing various options such as Pure Lead AGMs for top performance and Alloy AGMs for a more cost-effective solution. Examples of vehicles that use AGM batteries include the Buick Encore, Jeep Compass, and Ford F-150.

What are the differences between Lead-Acid, AGM, and Gel batteries?

Lead-Acid, AGM (Absorbent Glass Mat), and Gel batteries are all types of rechargeable batteries commonly used in a variety of applications. The differences between these three battery types are quite significant in terms of their construction and performance characteristics.

Lead-Acid batteries are the traditional type of battery, consisting of lead plates immersed in a sulfuric acid solution. While more affordable than AGM and Gel batteries, lead-acid batteries have a relatively shorter lifespan and require regular maintenance such as checking water levels and ensuring proper ventilation to prevent gas buildup.

AGM batteries, on the other hand, have absorbed glass mat separators between the lead plates, in which the electrolyte is absorbed into the matting rather than being free-flowing. This design makes AGM batteries spill-proof and leak-proof, offering better resistance to vibrations and shocks. AGM batteries also have a higher charge capacity, longer life expectancy, and require minimal maintenance compared to lead-acid batteries.

Gel batteries utilize a gelified electrolyte that immobilizes the acid solution, making them safe from leaks and spills. Gel batteries are known for their superior deep cycling capabilities, making them ideal for applications where the battery is regularly discharged deeply before recharging. While Gel batteries offer many of the same advantages as AGM batteries, they are generally more expensive and have slightly different performance characteristics.

Ultimately, the choice between Lead-Acid, AGM, and Gel batteries depends on factors such as budget, specific application needs, and desired performance attributes. Each type of battery has its own advantages and drawbacks, so it’s important to carefully consider these factors when selecting the right battery for your requirements.

What is the float charge voltage of a 12V flooded lead-acid battery?

The float charge voltage for a 12V flooded lead-acid battery is typically around 13.2 to 13.8 volts.

What is the bulk charge voltage of a 12V flooded lead-acid battery?

The bulk charge voltage for a 12V flooded lead-acid battery generally ranges from 14.4 to 14.8 volts.

What is the float charge voltage of a 12V AGM lead-acid battery?

The float charge voltage for a 12V AGM (Absorbent Glass Mat) lead-acid battery is usually around 13.2 to 13.5 volts.

What is the bulk charge voltage of a 12V AGM lead-acid battery?

The bulk charge voltage for a 12V AGM lead-acid battery typically ranges from 14.4 to 14.7 volts.