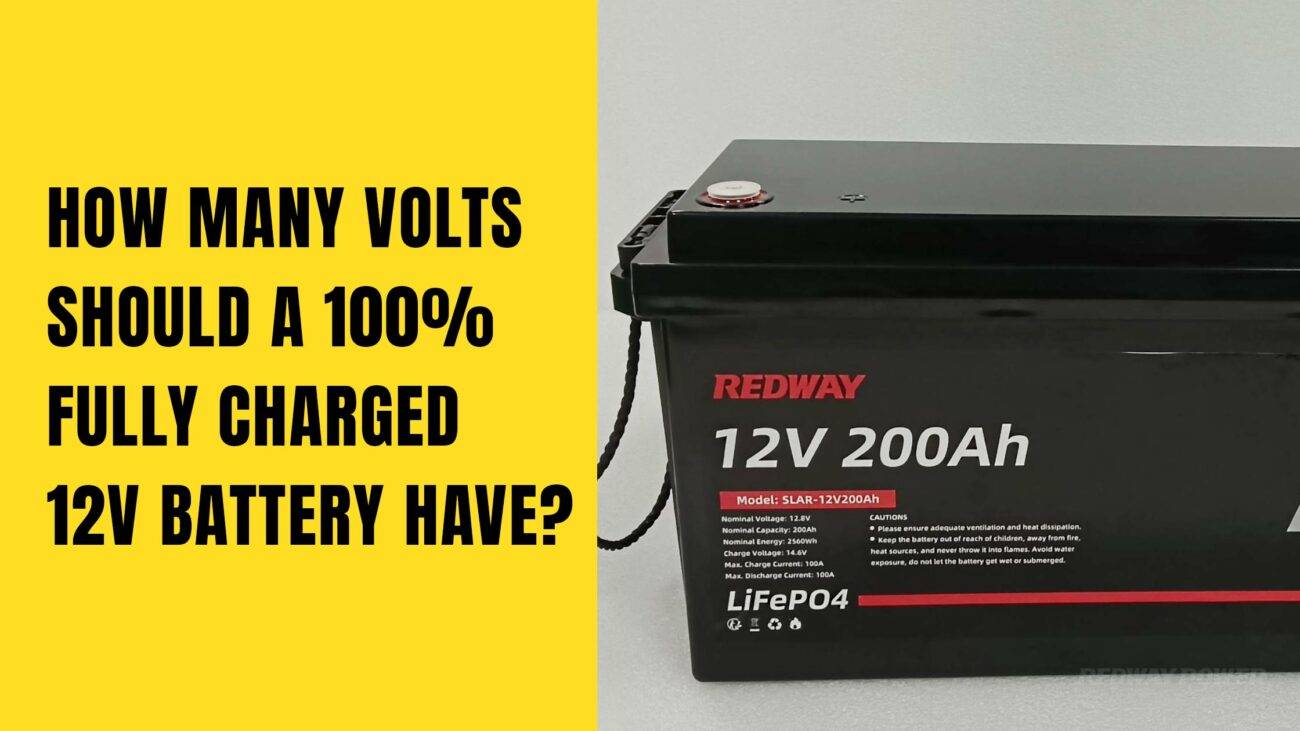

A 12V battery should be recharged at voltages ranging between 2.15V per cell (12.9V for a “12V” 6 cell battery) and 2.35V per cell (14.1V for a “12V” 6 cell battery). These voltages ensure proper charging without the risk of overcharging or damage to the battery.

Understanding voltage and its relation to battery charging

Voltage is the unit of current in your battery and is measured in volts. If you think of your battery as a water pipe, the voltage would be the water pressure in the pipe. This pressure makes the current flow through the battery, delivering power to your device.

Voltage is the unit of current in a battery, measured in volts. It represents the potential difference between the negative and positive terminals of the battery, similar to water pressure in a pipe. This voltage creates the force that allows current to flow through the battery, delivering power to a device.

- Voltage and Current: Voltage is the unit of current in a battery, measured in volts.

- Potential Difference: Voltage represents the potential difference between the battery terminals.

- Current Flow: Voltage creates the force that allows current to flow through the battery and power a device.

In conclusion, voltage is the unit of current in a battery, measured in volts. It represents the potential difference between the battery terminals and creates the force that allows current to flow through the battery, delivering power to a device. Understanding the relationship between voltage and battery charging is essential for proper battery usage and device operation.

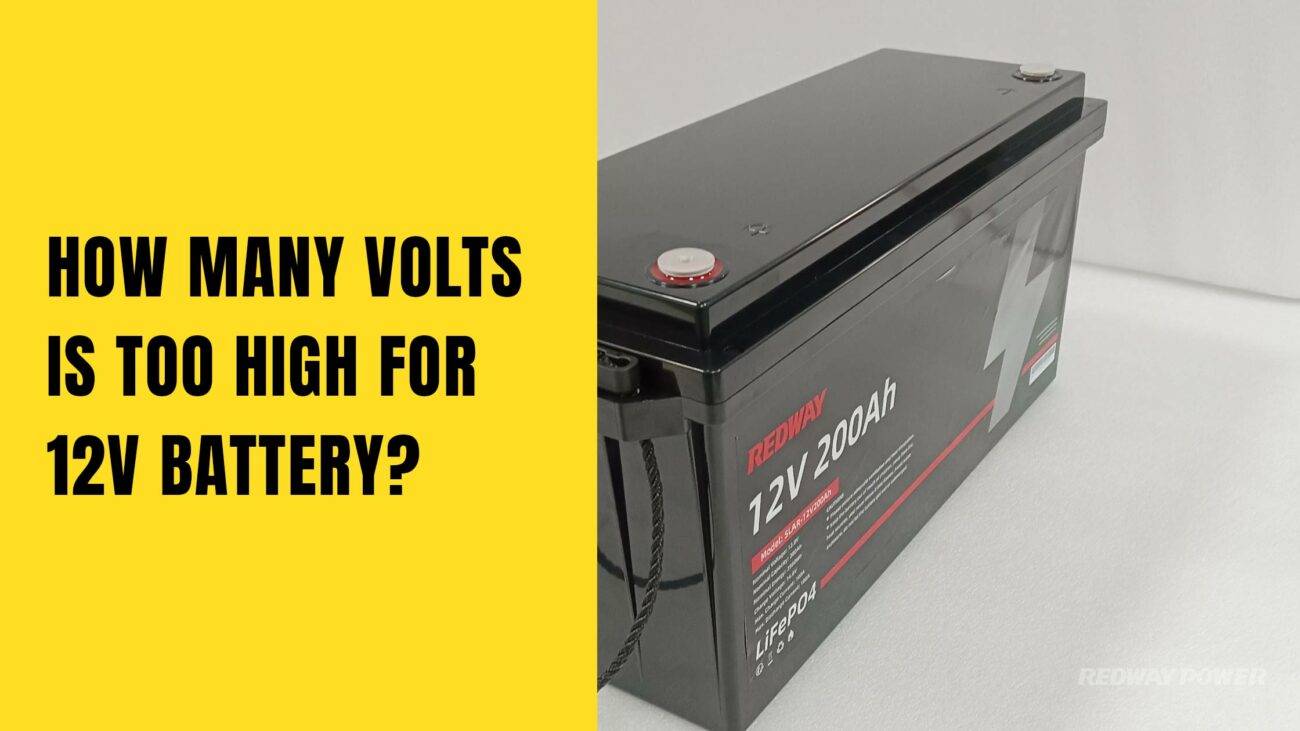

Factors that affect the ideal charging voltage for a 12V battery

The ideal charging

voltage for a 12V battery is influenced by factors such as battery chemistry, temperature, and the charging method used. Different battery types have specific voltage requirements for optimal charging, and temperature variations can affect the charging process.

The ideal charging voltage for a 12V battery depends on various factors. These factors include the chemistry of the battery, the temperature, and the charging method utilized. Understanding these factors helps determine the appropriate voltage for optimal charging and battery performance.

- Battery Type: Different battery types (LiFePO4, NMC, AGM, GEL, etc.) have specific voltage requirements for optimal charging.

- Temperature: Temperature variations can affect the charging process and may require adjustments to the charging voltage.

- Charging Method: The specific charging method used can influence the ideal charging voltage for a 12V battery.

In conclusion, the ideal charging voltage for a

12V battery is influenced by factors such as battery chemistry, temperature, and the charging method utilized. By considering these factors, one can determine the appropriate voltage for optimal charging and ensure optimal battery performance.

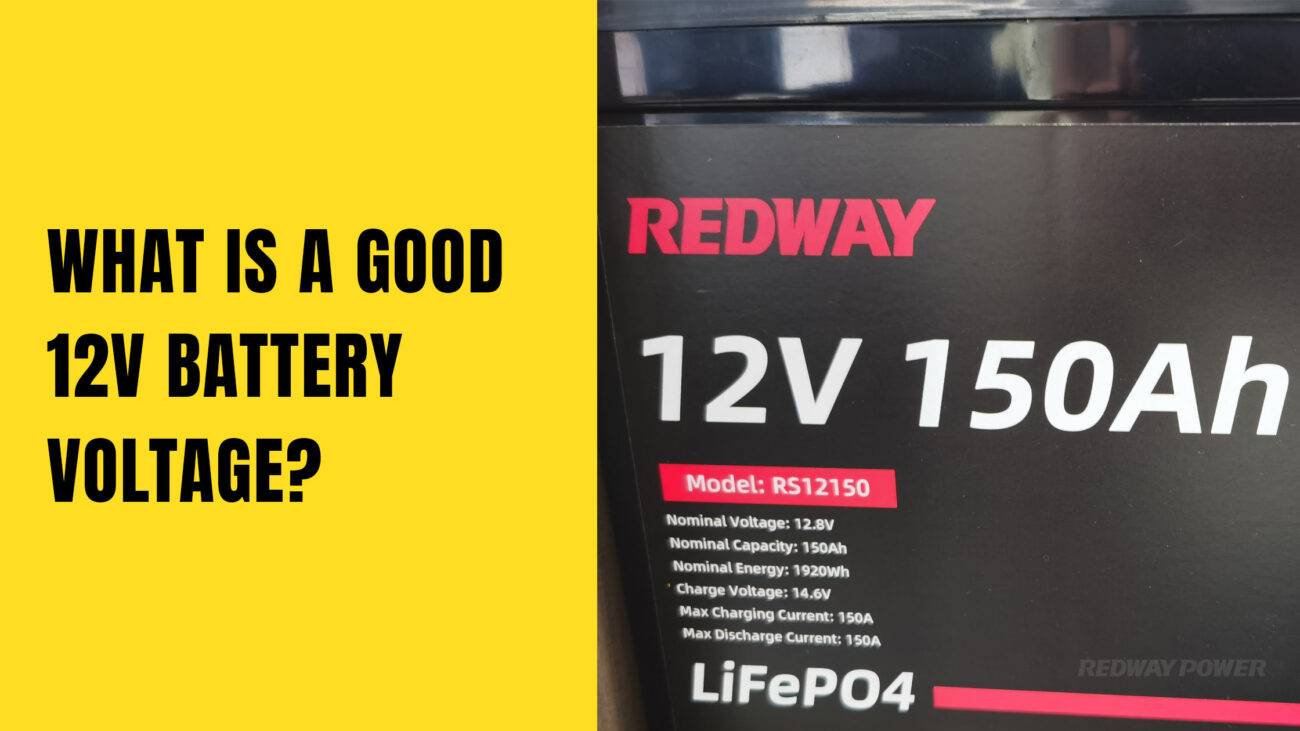

Recommended voltage range for charging a 12V battery

The recommended

voltage range for charging a 12V battery typically falls between 2.15V per cell (12.9V for a ’12V’ 6 cell battery) and 2.35V per cell (14.1V for a ’12V’ 6 cell battery). These voltages can be applied to a fully charged battery without overcharging or causing damage to the battery.

The recommended voltage range for charging a 12V battery generally falls between 2.15V per cell (12.9V for a “12V” 6 cell battery) and 2.35V per cell (14.1V for a “12V” 6 cell battery). Staying within this voltage range is crucial for safe and effective charging of the battery.

- Voltage Range: The recommended voltage range for charging a 12V battery is typically between 2.15V per cell and 2.35V per cell.

- Safe Charging: Staying within this voltage range ensures safe and effective charging without overcharging the battery.

- Damage Prevention: Charging within the recommended voltage range helps prevent damage to the battery during the charging process.

In conclusion, the recommended voltage range for charging a 12V battery ranges between 2.15V per cell and 2.35V per cell. It is important to adhere to this voltage range to ensure safe and effective charging while preventing damage to the battery. Following these guidelines helps maintain the longevity and performance of the battery.

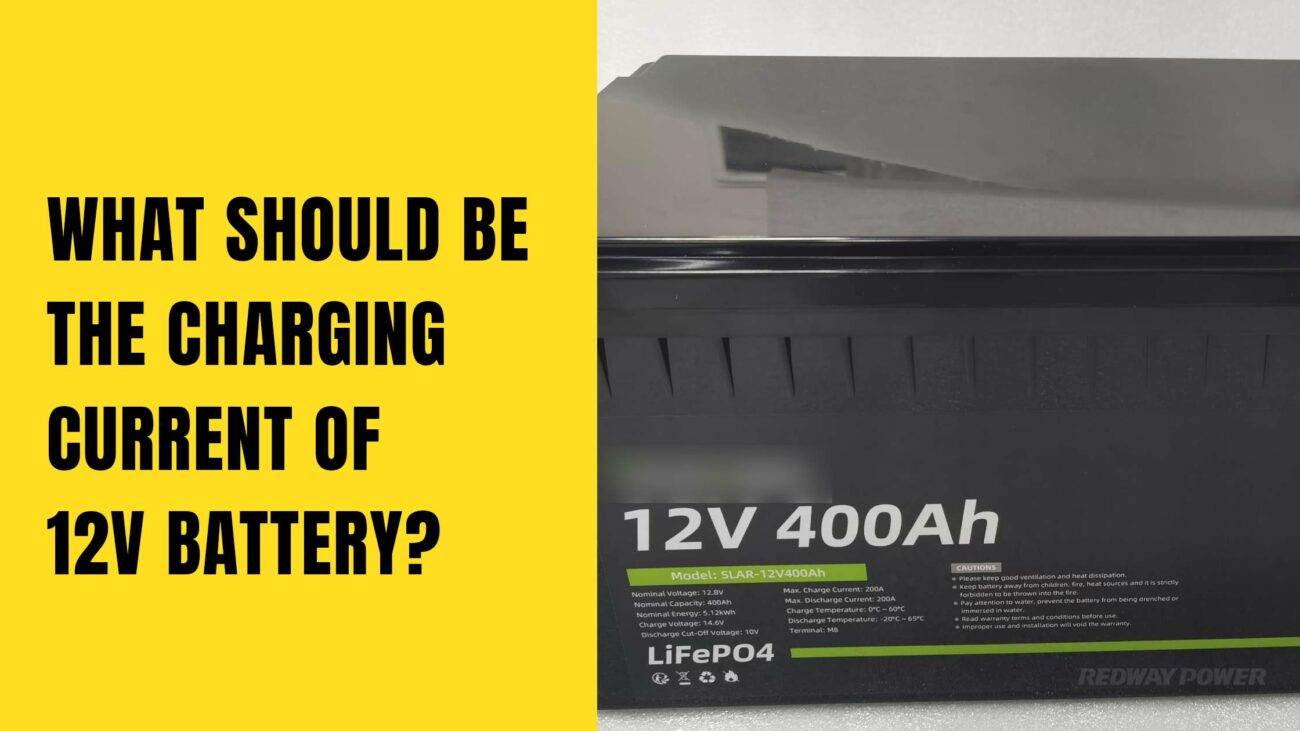

Different methods of charging a 12V battery

Charging a 12V battery can be done using different methods, including constant voltage charging, constant current charging, and a combination of constant voltage/constant current with or without a smart charging circuit. These methods offer flexibility in charging options and can be chosen based on battery type and specific charging requirements.

Charging a 12V battery involves different methods that offer flexibility in charging options. These methods include constant voltage charging, constant current charging, and a combination of constant voltage/constant current with or without a smart charging circuit. Understanding these methods is important for effective and efficient battery charging.

- Constant Voltage Charging: This method involves applying a steady voltage to the battery throughout the charging process.

- Constant Current Charging: Constant current charging involves supplying a steady current to the battery during the charging process.

- Combination Methods: Some charging methods combine constant voltage and constant current, offering a balance between voltage and current control for optimized charging.

In conclusion, charging a 12V battery can be done using different methods such as constant voltage charging, constant current charging, or a combination of both. These methods provide flexibility and control over the charging process, ensuring effective and efficient charging for the battery.

Importance of monitoring voltage during the charging process

Monitoring voltage during the charging process is important to check the battery status, control the charge and discharge equipment, and ensure traceability across battery production processes.”

Monitoring voltage during the charging process is of utmost importance to ensure optimal battery performance. By keeping a close eye on the voltage, we can check the battery status, control the charge and discharge equipment, and maintain traceability across battery production processes.

- Battery Status Check: Monitoring voltage allows us to assess the battery’s status and detect any abnormalities.

- Equipment Control: Voltage monitoring helps control the charge and discharge equipment for efficient battery charging.

- Traceability in Production: By monitoring voltage, we can ensure traceability across battery production processes.

In conclusion, monitoring voltage during the charging process is essential for checking battery status, controlling equipment, and maintaining traceability in battery production. By actively monitoring voltage, we can ensure optimal battery performance and longevity.